VPD300E Eye Pad Making Machine

The VPD300E Eye Mask Making Machine combines cutting-edge sealing and cutting technology with automatic packaging capabilities, ideal for automatic eye patch production.

VPD300E Eye Pad Making Machine

As a versatile sealing and cutting machine, the VPD300E eye mask making machine offers automatic eye patch production solutions, minimizing manual intervention and enhancing production efficiency. VPD300E seal packaging machine is an ideal choice for businesses seeking reliable sealing machine suppliers and looking to automate their eye patch manufacturing operations. With its automated features, the VPD300E eye patch making machine guarantees high-quality output while optimizing manufacturing workflows.

Application: For non-woven fabric eye patches making

Bag Type: Four-side Seal

Speed: 80-120 bags/min

Power: 15KW

The VPD300E Eye Patch Making Machine seamlessly integrates automatic eye patch production and packaging, offering customization options for different types of eye patches. Designed explicitly for non-woven material eye patches, the VPD300E eye mask making machine operates at a high speed of 80-120 bags per minute. The sealing and cutting machine utilizes advanced four-side sealing technology to ensure quality and efficiency in the manufacturing process. Ideal for businesses seeking automatic eye patch production solutions, the VPD300E eye pad making machine combines reliability with versatility to meet diverse market demands.

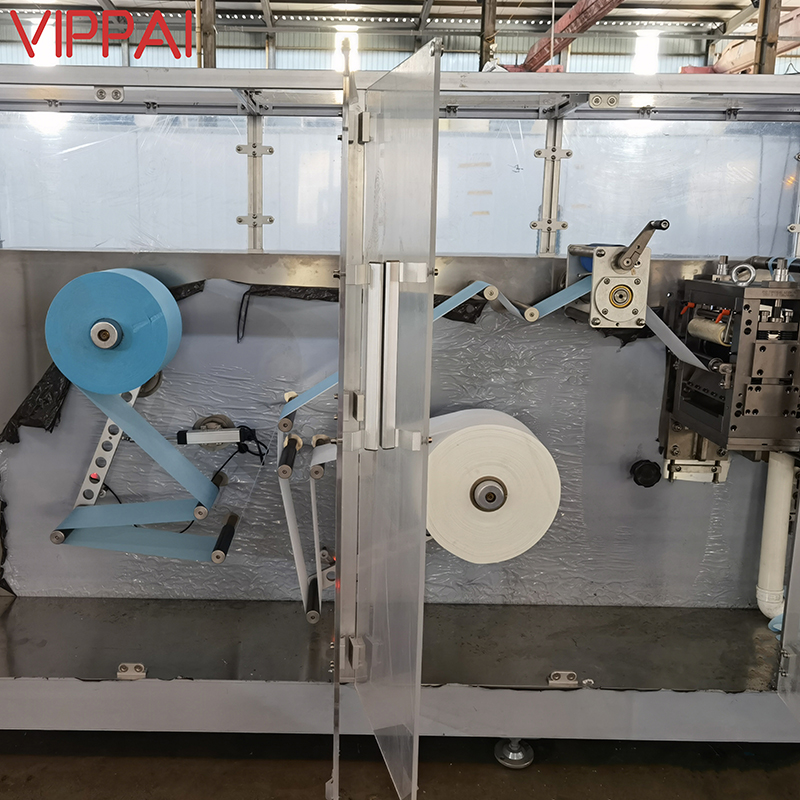

The whole line process:

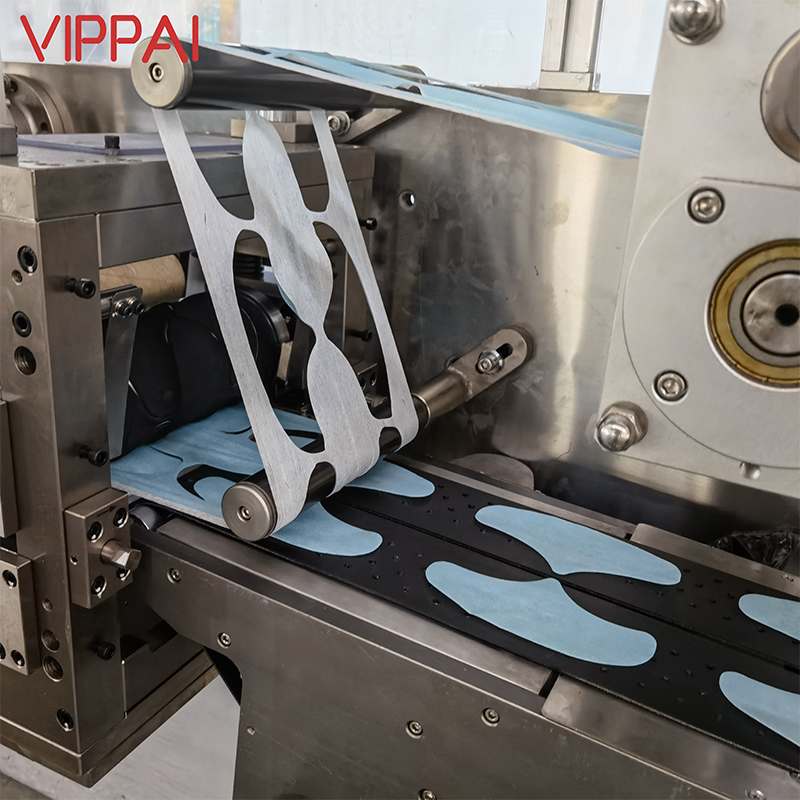

Step 1: Cut the non-woven fabric into an eye patch shape.

Step 2: Liquid adding.

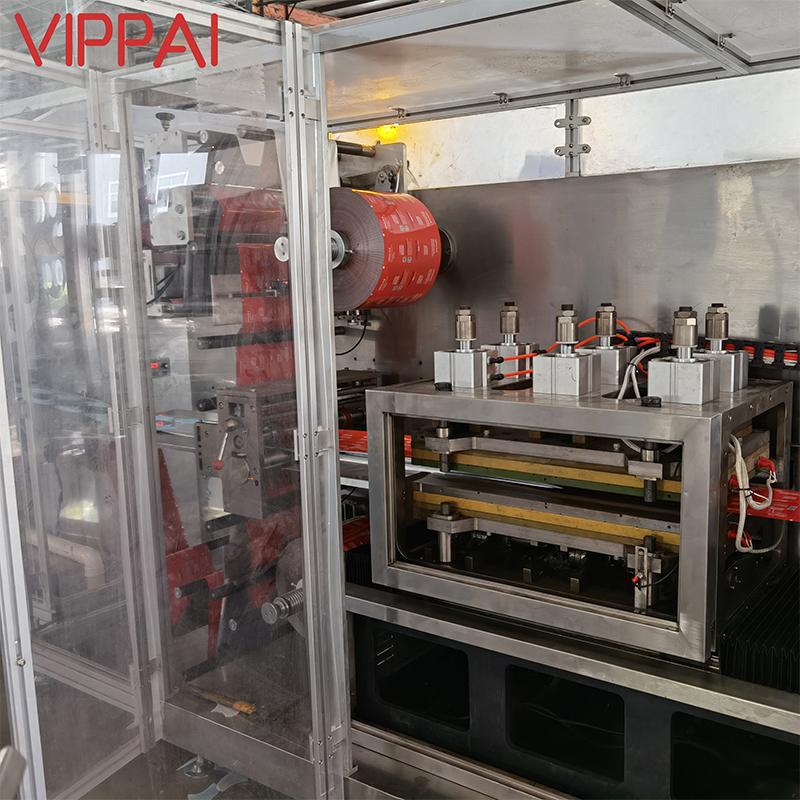

Step 3: Cut the packaging film.

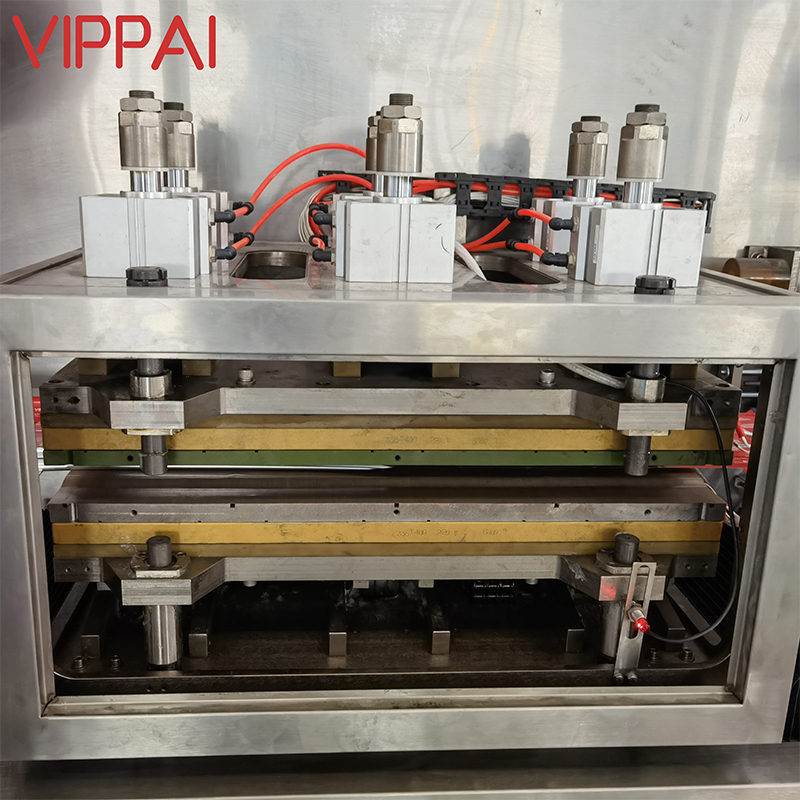

Step 4: Put the eye patches and heat seal the bag.

Step 5: Cut and output finished eye patches.

Benefits of Vippai VPD300E Eye Mask Making Machine:

1.The VPD300E eye patch making machine features a Japanese Yaskawa servo motor, ensuring simple, safe, and reliable parameter adjustment via a touchscreen interface.

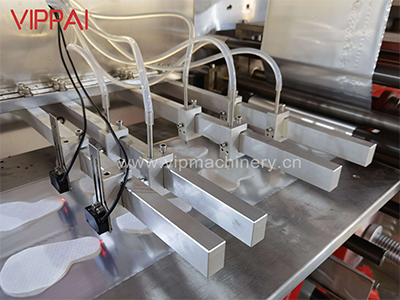

2.Vippai VPD300E sealing and cutting machine’s reciprocating heat sealing mechanism allows ample time for large-area sealing, providing strong, smooth, and aesthetically pleasing seals that accommodate a variety of materials.

3.The Vippai sealing and packing machine includes an alarm for film shortages and automatic stop capabilities. VPD300E eye mask making machine corrects deviations through two-point cursor tracking automatic calibration, ensuring safety and stability.

4.With versatile packaging capabilities, Vippai sealing and packing machine facilitates fast and convenient mold switching, making our eye mask making machine highly adaptable and compatible with various packaging specifications.

After-sales Service

VIPPAI not only provides high-quality eye patch making machines but also ensures comprehensive support for partners:

1.Usage Guidance: Upon delivery of the eye mask making machine, partners receive installation and operation videos along with a detailed manual. This ensures they can effectively operate the Vippai eye mask making machine from the outset.

2.Reliable Warranty: VIPPAI offers a one-year warranty on all electrical parts of our patch manufacturing machines. In case of any quality issues within this period, our partners benefit from free repair services. If necessary, defective electrical parts will be promptly replaced.

3.Technical Support: As a leading sealing machine supplier, VIPPAI provides continuous technical support. If eye mask making machine issues arise, our engineers offer professional online guidance to troubleshoot problems. If a resolution cannot be achieved remotely, VIPPAI arranges for engineers to visit partners' locations for repair.

This commitment to support and service ensures that partners can rely on VIPPAI not only for advanced sealing and packing machines but also for ongoing assistance to maximize operational efficiency and minimize downtime.

|

Model |

VPD-300E |

|

Packing Form |

horizontal four side sealing |

|

Packing speed |

80-120 bags/min |

|

Packaging material |

Composite materials such as composite film, aluminized film, polyethylene/polypropylene, etc. |

|

Inner Material |

non-woven fabrics |

|

Power Supply |

380V 50Hz |

|

Total Power |

15 kw |

|

Weight |

5500 kg |

|

Overall Dimensions |

7400mm*1200mm*1520mm |

Click below to learn about how the VPD300E eye patch making machine works.