VPD-400 Face Sheet Mask Machine(Bag Making or Bag Giving)

The VPD-400 Face Sheet Mask Machine integrates advanced features such as automatic bag filling, sealing, and packing capabilities.

VPD-400 Face Sheet Mask Machine(Bag Making or Bag Giving)

Vippai VPD-400 Face Sheet Mask Machine is a cutting-edge solution for producing high-quality face sheet masks. Designed for efficiency and precision, our automatic bag filling machine is ideal for both manufacturing and packaging cosmetic face masks, ensuring consistent quality and hygiene. The VPD-400 automatic filling and sealing machine is tailored for the cosmetics and skincare industries, offering reliable performance in face pack making and packaging processes.

Speed: 3000-4200 bags/hour

Power: 18KW

Product Size: (100-225) *(100-180) mm(L*M)

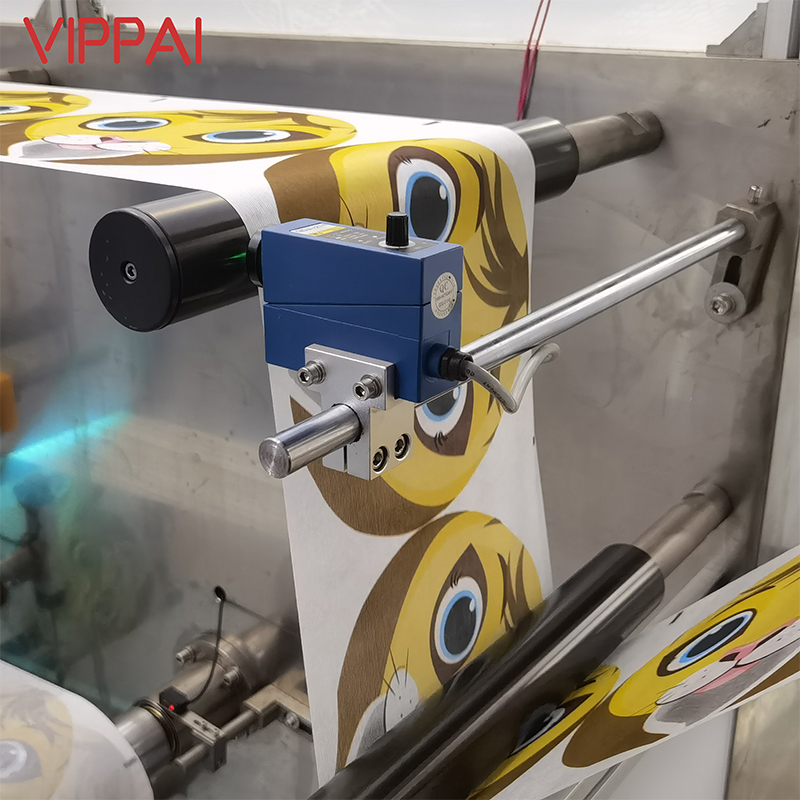

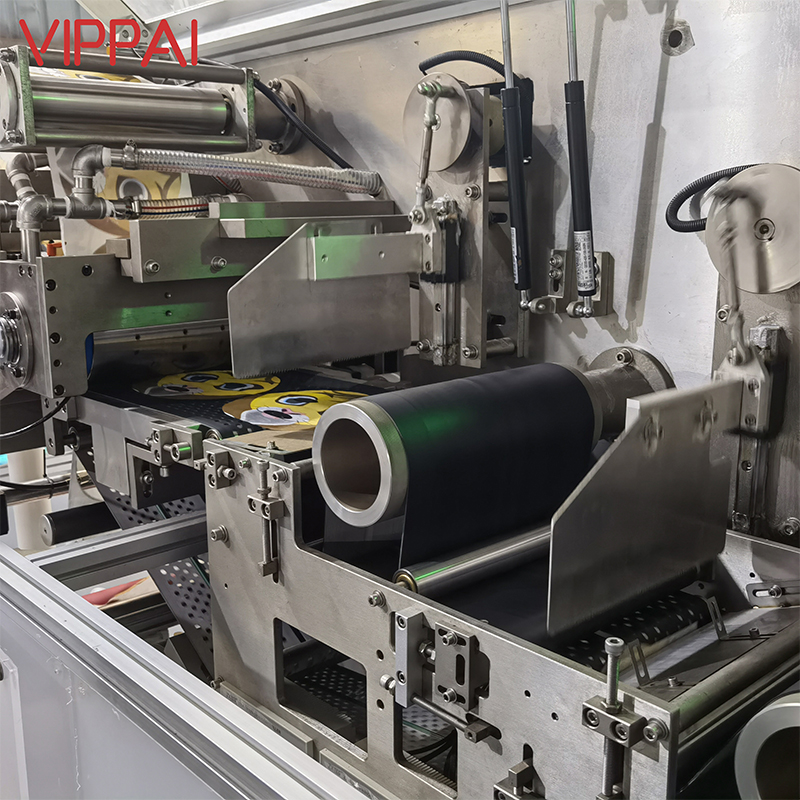

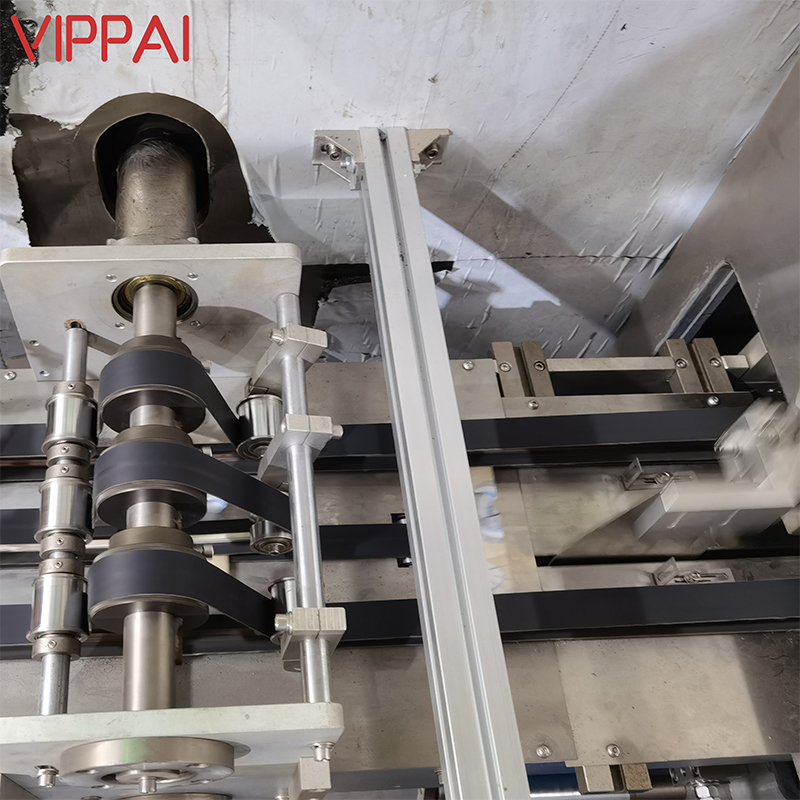

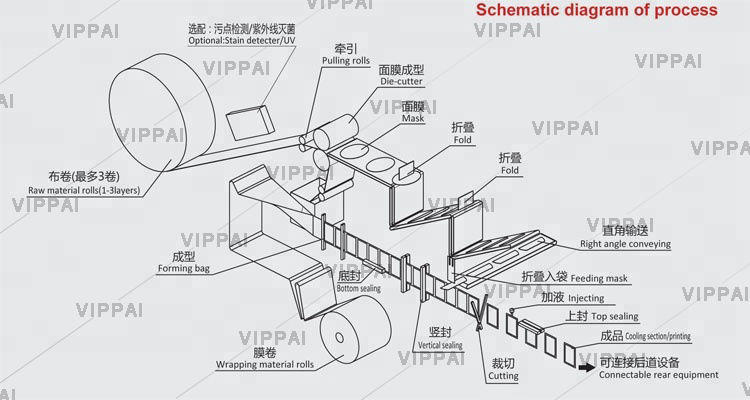

The VPD-400 Face Sheet Mask Machine is an advanced automatic face sheet mask packaging solution capable of manufacturing and packaging sheet masks efficiently. Our automatic bag filling machine VPD-400 adheres to pharmaceutical-grade GMP production standards, handling processes from roll film feeding to testing, film cutting and forming, mask folding, online bag making (or using pre-made bags), liquid essence addition, bag sealing, and more.

This versatile automatic filling and sealing machine replaces traditional manual workshop equipment such as punching machines, forming machines, folding machines, filling machines, and sealing machines. By doing so, Vippai's fully automatic packing machine reduces labor requirements by 8-15 workers and minimizes workshop space usage. Notably, the VPD-400 face pack making machine effectively addresses secondary pollution issues during production. Cooperating Clients: Korea Mediheal, JAYJUN Cosmetic, New Zealand Essano, US Yesto, Poland Marion Sp. z o.o, UK Egg Cream Mask, and so on.

VPD-400 Face Sheet Mask Machine’s Benefits

1.With the VPD-400 face mask sheet making machine, automatic mask production packaging eliminates the need for 8-15 workers, significantly streamlining production processes and enhancing efficiency.

2.The entire production process is conducted within a controlled environment to ensure the face sheet mask packaging is free from contamination.

3.The Vippai entire face sheet mask machine fully complies with GMP (Good Manufacturing Practice) certification requirements.

4.Our automatic bag filling machines VPD-400 save labor costs and reduce packaging material expenses by 20-30%.

5.The fully automatic packing machine allows for easy adjustment when changing bag types and offers broad compatibility with various convenient bag formats.

6.The entire automatic filling and sealing machine features servo settings that are stable and user-friendly, ensuring ease of use and consistent performance.

7.The face pack making machine is designed with a balcony layout, separating the drive station from the workstation for enhanced safety and reliability.

8.The face sheet mask machine VPD-400 filling process allows for manual inspection with the naked eye, enabling the detection and removal of black spots or other unqualified products through online visual inspection.

9.Our face mask sheet making machine uses a high-end metering pump for precise filling, achieving an accuracy of plus or minus 1 gram.

After-sales Service

VIPPAI offers our partners high-quality face sheet mask machines with comprehensive after-sales support and technical assistance.

1.Usage Guidance: Upon delivery of the face mask sheet making machine, we provide installation and operational videos, along with a detailed machine manual. These resources ensure that our partners can effectively operate the face mask sheet machine.

2.Reliable Warranty: We provide a one-year warranty on all electrical parts of Vippai fully automatic packing machines. If any quality issues arise within this period, we offer free repair services. Additionally, all electrical components are covered by our warranty, ensuring prompt replacement if needed.

3.Technical Support: In case of face mask sheet making machine failure, Vippai engineers offer professional online troubleshooting. If the issue cannot be resolved remotely, we arrange for engineers overseas to conduct repairs. This ensures minimal downtime and supports ongoing operational efficiency for our partners.

|

Model |

VPD-400 |

|

Packing Bag Style |

Flat bag, corner pocket |

|

Packing Material |

Composite materials such as composite film, aluminized film, polyethylene/polypropylene, etc. |

|

Packing Material Size |

L: 100-225 mm W: 100-180 mm |

|

Packing Speed |

3000-4200 bags/hour |

|

Liquid Filling Capacity |

0~50ml the essence / liquid addition accuracy is + 1ml, and the liquid can be used below the viscosity coefficient 20000cp |

|

Power Supply |

380V 50/60HZ 18KW, three phase |

|

Machine size |

7300x2860x2230 mm |

|

Weight |

7000 kg |

Click below to learn about how VPD-400 face mask making machine works.