In the rapidly growing market of wet tissue products, particularly in sectors such as healthcare, personal hygiene, and cleaning, the need for high-quality, efficient production equipment is more critical than ever. Vippai's VPD-800A Alcohol Pad Making Machine is a standout wet tissue making machine solution, designed to meet the diverse needs of modern manufacturers. Here's a detailed look at why investing in this machine could be a transformative decision for your production line.

High-Speed Production Capability

One of the most compelling features of the VPD-800A is its ability to produce between 800 to 1200 pieces per minute. This high-output capability ensures that you can meet large orders and market demands without sacrificing quality. For businesses looking to scale, the VPD-800A offers the kind of throughput that can lead to significant growth in both output and revenue.

Flexible Production Options

Flexibility in manufacturing is often the key to both efficiency and customer satisfaction. The VPD-800A allows the non-woven material to be folded in half or doubled over. This adaptability in the folding process not only caters to various product specifications but also allows businesses to diversify their product lines with ease. Whether your market demands smaller, more compact wipes or larger, more absorbent ones, this machine can be adjusted to meet those needs seamlessly.

Adherence to Industry Standards

The reliability of manufacturing equipment is non-negotiable, especially in industries that require stringent hygiene standards. Vippai ensures that the VPD-800A and all its main electrical components strictly adhere to industry standards. This compliance not only enhances the machine's reliability but also ensures that the products manufactured are safe and consistent in quality, crucial for maintaining consumer trust and regulatory approval.

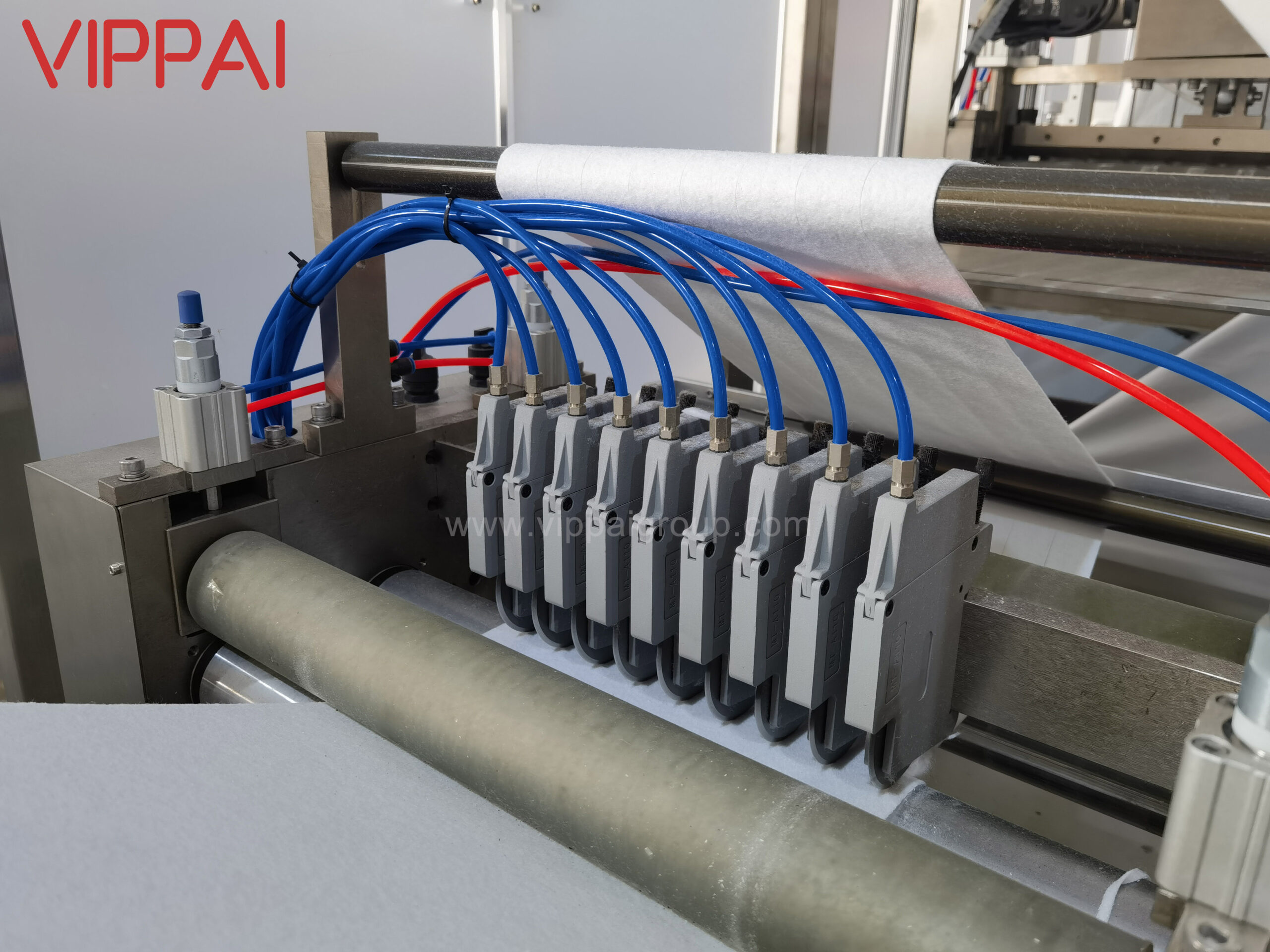

Enhanced Operational Safety and Cleanliness

Safety and cleanliness are paramount in the production of wet tissues, which are often used in sensitive environments such as hospitals and clinics. The VPD-800A features a glass cover that encases the operational components, enhancing safety for operators and maintaining a clean production environment. This design minimizes the risk of contamination and ensures that the product remains hygienic throughout the manufacturing process.

Why Choose Vippai's VPD-800A?

Investing in the right manufacturing technology can significantly impact your business's capability to deliver high-quality products efficiently. Here are a few reasons why the VPD-800A could be your best choice:

Scalability: The machine's high-speed production capability makes it an excellent investment for businesses planning to scale up.

Product Quality: With precise folding options and strict adherence to industry standards, the machine consistently produces high-quality wet tissues.

Operational Efficiency: The integration of advanced safety and cleanliness features ensures that downtime is minimized and productivity is maximized.

Market Versatility: The flexibility in production allows manufacturers to easily switch between different product specifications, making it easier to adapt to changing market trends or customer needs.

Conclusion

For manufacturers aiming to elevate their production capabilities in the wet tissue market, Vippai's VPD-800A Alcohol Pad Making Machine offers a combination of speed, flexibility, safety, and compliance that is hard to match. By investing in this advanced equipment, you can not only enhance your operational efficiency but also gain a competitive edge in a fast-growing industry. Trust Vippai to deliver technology that not only meets but exceeds the demands of modern wet tissue production.