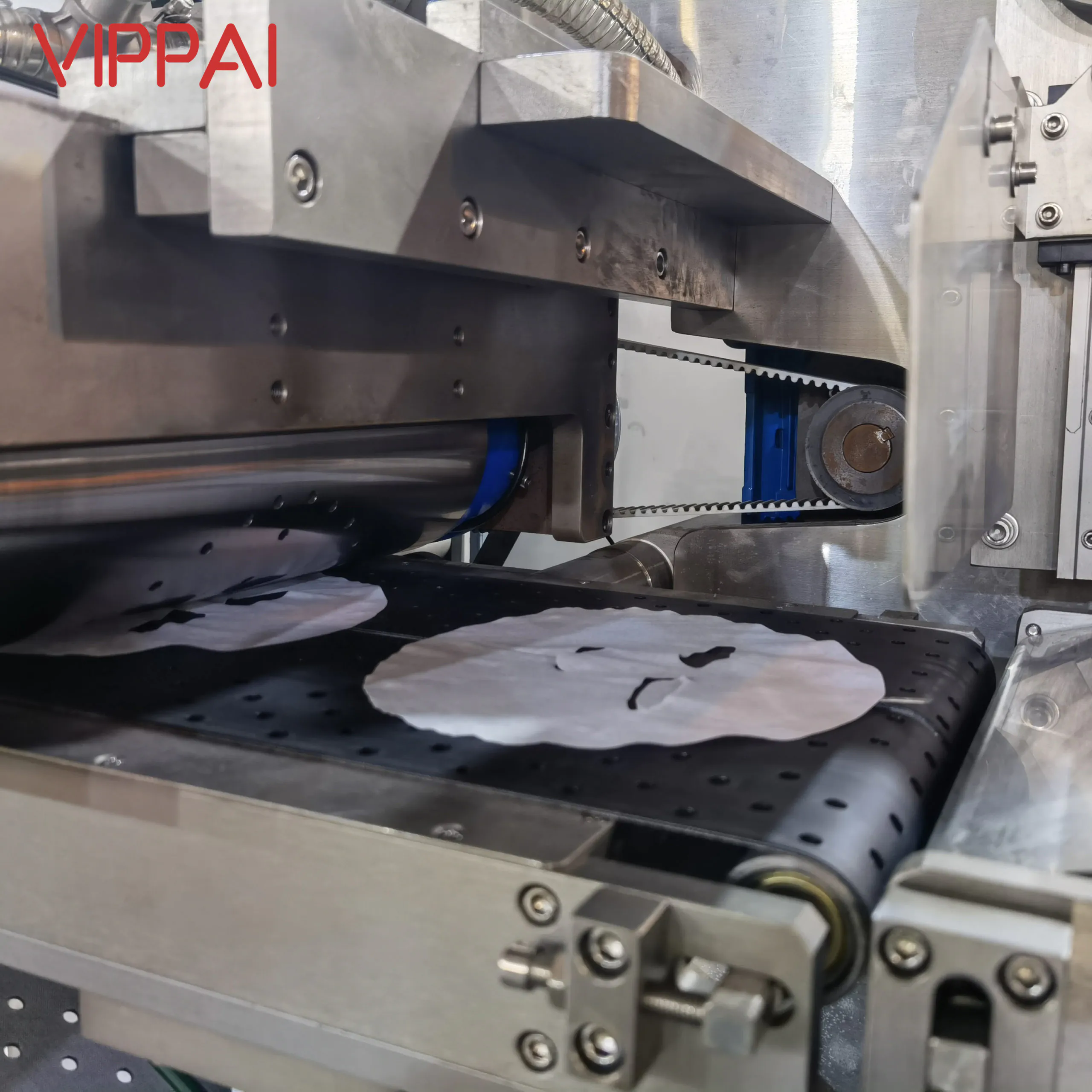

In the competitive landscape of cosmetic manufacturing, especially in the realm of facial masks, the significance of using an advanced and reliable packing machine cannot be overstated. Vippai's facial mask packing machine: VPD98-4 can offer a blend of precision, innovation, and compliance, setting new standards in the industry. Here's a detailed look at why Vippai's packing machine is the ideal choice for businesses aiming to enhance their production efficiency and product quality.

- Enhanced Stability with Adjustable Servo Settings

One of the standout features of the Vippai facial mask packing machine is its adjustable servo settings. This feature allows for greater control and stability during the packing process, making the machine exceptionally user-friendly. Adjustability ensures that the machine can be fine-tuned according to specific product requirements or environmental conditions, leading to consistently high-quality packaging and reduced downtime.

- Designed for Safety and Operational Reliability

Safety in the workplace is paramount, and Vippai's design reflects this priority. The machine features a separate balcony for the drive and workstations, segregating the mechanical and operational areas. This not only enhances the safety of the machine operators but also increases the overall reliability of the machine. By minimizing the risk of accidents and breakdowns, this design ensures a smoother, uninterrupted production flow.

- Precise Filling Accuracy with High-End Metering Pump

Accuracy in filling is crucial for maintaining product quality and customer satisfaction, especially in the beauty industry where consistency can define brand reputation. The Vippai beauty mask packing machine is equipped with a high-end metering pump that achieves precise filling accuracy within a tolerance of ±1 gram. This precision ensures that each package contains exactly the right amount of product, reducing waste and ensuring that customers receive what they expect every single time.

- Compliance with GMP Certification Requirements

For cosmetic manufacturers, adhering to Good Manufacturing Practices (GMP) is not just about meeting regulatory requirements — it's about ensuring that products are consistently produced and controlled according to quality standards. Vippai's automated face mask packaging machine is fully compliant with GMP certification requirements. This compliance guarantees that the machine meets rigorous standards for production quality and hygiene, which is essential for manufacturers looking to market their products globally.

Conclusion

Choosing the right machinery for your production line is a critical decision that can affect your business's efficiency, product quality, and bottom line. Vippai's facial mask packing machine offers a combination of technological sophistication, safety, precision, and regulatory compliance, making it a top choice for cosmetic companies worldwide. By investing in Vippai's technology, businesses not only optimize their production processes but also enhance their product's marketability by consistently meeting high standards of quality and safety. Whether you're scaling up production or aiming to improve product quality, Vippai's packing machine is designed to meet the diverse needs of the modern cosmetic industry.