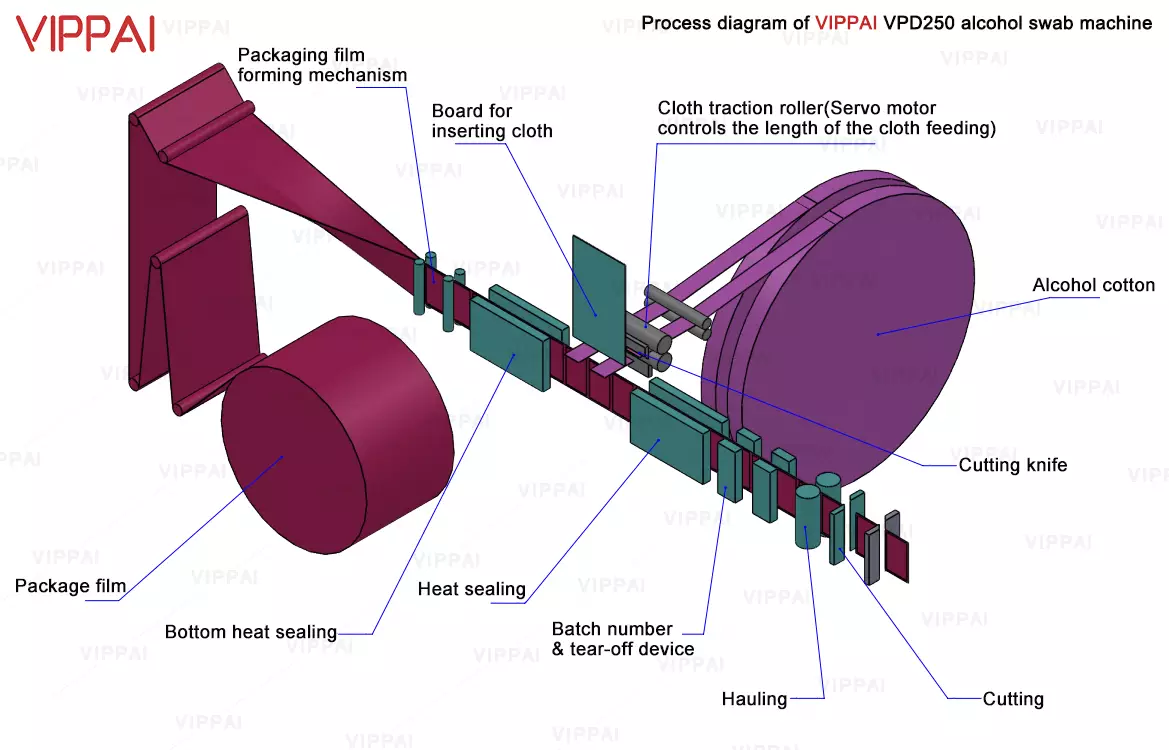

In the fast-paced healthcare industry, the demand for high-quality alcohol swabs is on the rise. Vippai introduces the VPD-250D Full Auto Alcohol Swab Making Machine, a state-of-the-art solution designed for efficient and precise right angle packaging. With a remarkable production speed of 100-150 bags per minute, this advanced machine produces one-piece four-side seal wipes, making them portable and hygienic. Discover how Vippai alcohol swab making machine VPD-250D is redefining the alcohol swab manufacturing process, offering versatility and cost-effectiveness to meet diverse market needs.

Intelligent Design and Precision

Vippai's VPD-250D stands out with its intelligent and accurate design. Equipped with Japan Yaskawa servo motor and Yaskawa Motion Controller, this advanced technology enhances machine intelligence and improves productivity. The speed of 100-150 bags per minute ensures swift production without compromising on precision and quality. The integration of Yaskawa's cutting-edge servo motor technology ensures smooth and precise operation, guaranteeing consistent and reliable alcohol swab production.

Versatility with Adjustable Mould

The VPD-250D Alcohol Swab Making Machine features an adjustable mould, allowing manufacturers to produce various sizes of wet wipes to meet diverse market demands. The machine can create alcohol swabs with dimensions ranging from (40-140) *(40-110) mm(L*W), providing versatility and adaptability for different applications. Whether it's disinfectant wipes, alcohol pads, glass lens wipes, feminine care wipes, male delay wipes, or makeup remover wipes, VPD-250D delivers top-notch performance in every production run.

Right Angle Packaging for Cost-Effectiveness

Vippai's VPD-250D offers the advantage of right angle packaging, which is both cost-effective and highly productive. Compared to rounded corner devices, the right angle knife option provides higher efficiency at a reduced cost, making it an optimal choice for manufacturers seeking to enhance productivity without compromising on quality. The machine's capability to perform up to 10 vertical folds and 4 horizontal folds allows for flexible folding of non-woven fabric, ensuring precise and seamless packaging.

Exceptional Features for Enhanced Performance

The VPD-250D incorporates several exceptional features that elevate its performance and reliability. The twice heat sealing feature ensures secure sealing to prevent liquid leakage, preserving the integrity of the alcohol swabs and promoting user confidence. Moreover, the machine and all main electrical parts strictly adhere to CE standards, ensuring compliance with international quality and safety regulations.

The VPD-250D Alcohol Swab Making Machine is designed with a glass cover to promote safe and clean operation, safeguarding the hygiene and integrity of the manufacturing environment. Manufacturers can also choose between the "-" and "v" edging forms for the package bag, providing flexibility to cater to specific packaging preferences.

Conclusion

Vippai's VPD-250D Alcohol Swab Making Machine redefines the alcohol swab manufacturing process, offering precision, efficiency, and versatility in right angle packaging. With intelligent design, adjustable mould, right angle knife option, and exceptional features, VPD-250D ensures seamless production of high-quality alcohol swabs. Invest in Vippai's VPD-250D and experience the future of alcohol swab making with enhanced productivity and cost-effectiveness. Elevate your manufacturing capabilities and meet the growing demands of the healthcare industry with Vippai's commitment to excellence and innovation.