At Vippai, we are committed to delivering innovative solutions that enhance productivity in the beauty and personal care industries. Our VPD300E Eye Mask Making Machine is a prime example of our dedication to quality and efficiency. Designed with advanced technology and user-friendly features, this sealing and packing machine offers a range of benefits that make it an essential tool for manufacturers of eye masks.

Advanced Technology for Easy Operation

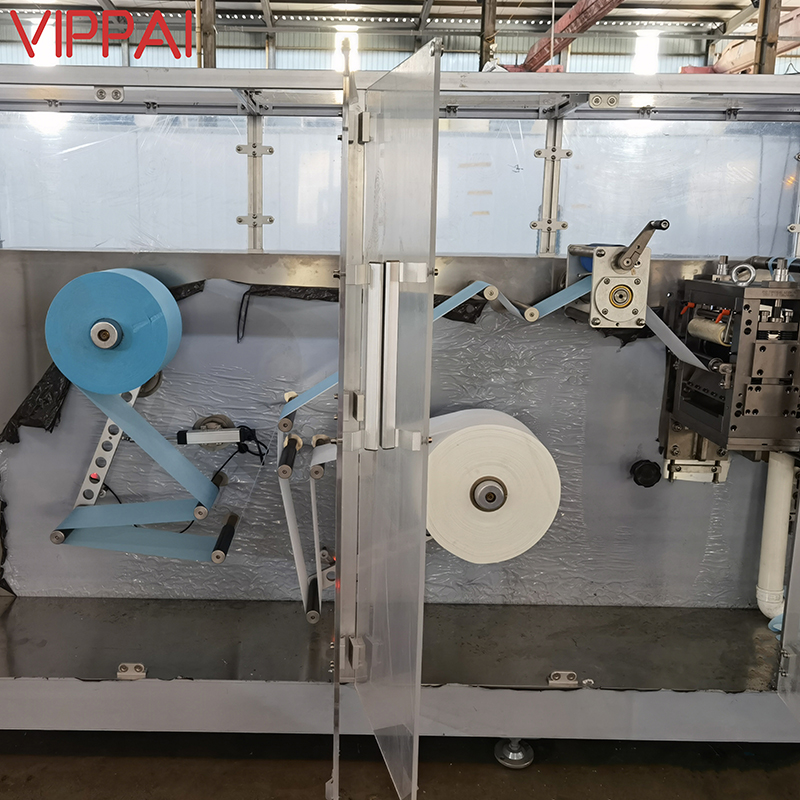

One of the standout features of the VPD300E eye patch making machine is its integration of a Japanese Yaskawa servo motor. This technology ensures simple, safe, and reliable parameter adjustment through an intuitive touchscreen interface. By making it easier for operators to manage settings, we enhance the overall efficiency of the production process.

Our commitment to user-friendly technology means that even those new to the packaging industry can operate the sealing and packing machine with ease. This simplicity not only reduces the likelihood of operational errors but also allows for faster training of new personnel, further improving productivity on the production line.

High-Quality Sealing for Superior Packaging

The Vippai VPD300E sealing and packing machine is equipped with a reciprocating heat sealing mechanism that provides ample time for large-area sealing. This feature ensures strong, smooth, and aesthetically pleasing seals, accommodating a variety of materials. Our machine's ability to create high-quality seals is crucial for maintaining the integrity of the eye masks, ensuring they remain effective and appealing to consumers.

We understand that first impressions matter in the beauty industry, and the quality of packaging can significantly influence consumer perception. With the VPD300E, businesses can deliver eye masks that not only perform well but also look professional, enhancing brand reputation and market competitiveness.

Safety and Versatility in Production

Safety and versatility are at the forefront of the VPD300E design. Our sealing and packing machine includes an alarm for film shortages and automatic stop capabilities, ensuring that production halts if any issues arise. This feature minimizes waste and ensures that operators can address problems promptly, maintaining continuous operation without compromising safety.

Additionally, the VPD300E eye mask making machine incorporates two-point cursor tracking automatic calibration, which corrects deviations during operation. This capability ensures consistent performance and stability, allowing manufacturers to produce eye masks with precision.

The versatility of our sealing and packing machine also facilitates fast and convenient mold switching. This adaptability makes the VPD300E suitable for various packaging specifications, allowing businesses to respond swiftly to market trends and consumer demands.

Conclusion

At Vippai, we take pride in our ability to provide innovative solutions that enhance efficiency and quality in the packaging process. The VPD300E Eye Mask Making Machine exemplifies our commitment to excellence, offering advanced technology, high-quality sealing, and versatile production capabilities. By investing in our sealing and packing machine, manufacturers can improve their operational efficiency while delivering top-notch eye masks to consumers. Join us in redefining the standards of beauty packaging, and let Vippai be your trusted partner in success.