At Vippai, we are dedicated to revolutionizing the alcohol pad manufacturing industry with our state-of-the-art equipment. Our flagship product, the VPD-800A High-Speed Multi-line Alcohol Pad/Swab Machine (Roller Cylinder), exemplifies our commitment to quality and efficiency. Designed with cutting-edge technology, our pad manufacturing machine addresses the critical needs of the medical and pharmaceutical sectors, ensuring that our clients can meet stringent industry standards.

Intelligent and Precise Operations

The VPD-800 Alcohol Swab Machine employs a servo motor for intelligent and precise operation during production. This advanced technology enhances efficiency by ensuring that every step of the manufacturing process is executed with accuracy. In industries where precision is paramount, such as medical and pharmaceutical applications, our machine stands out by maintaining high standards throughout production.

This intelligent design not only accelerates the manufacturing process but also reduces the risk of errors, resulting in consistent quality across all produced pads. By integrating smart technology into our pad manufacturing machine, we empower our clients to elevate their production capabilities and meet the increasing demands of their markets.

Versatile Production Capabilities

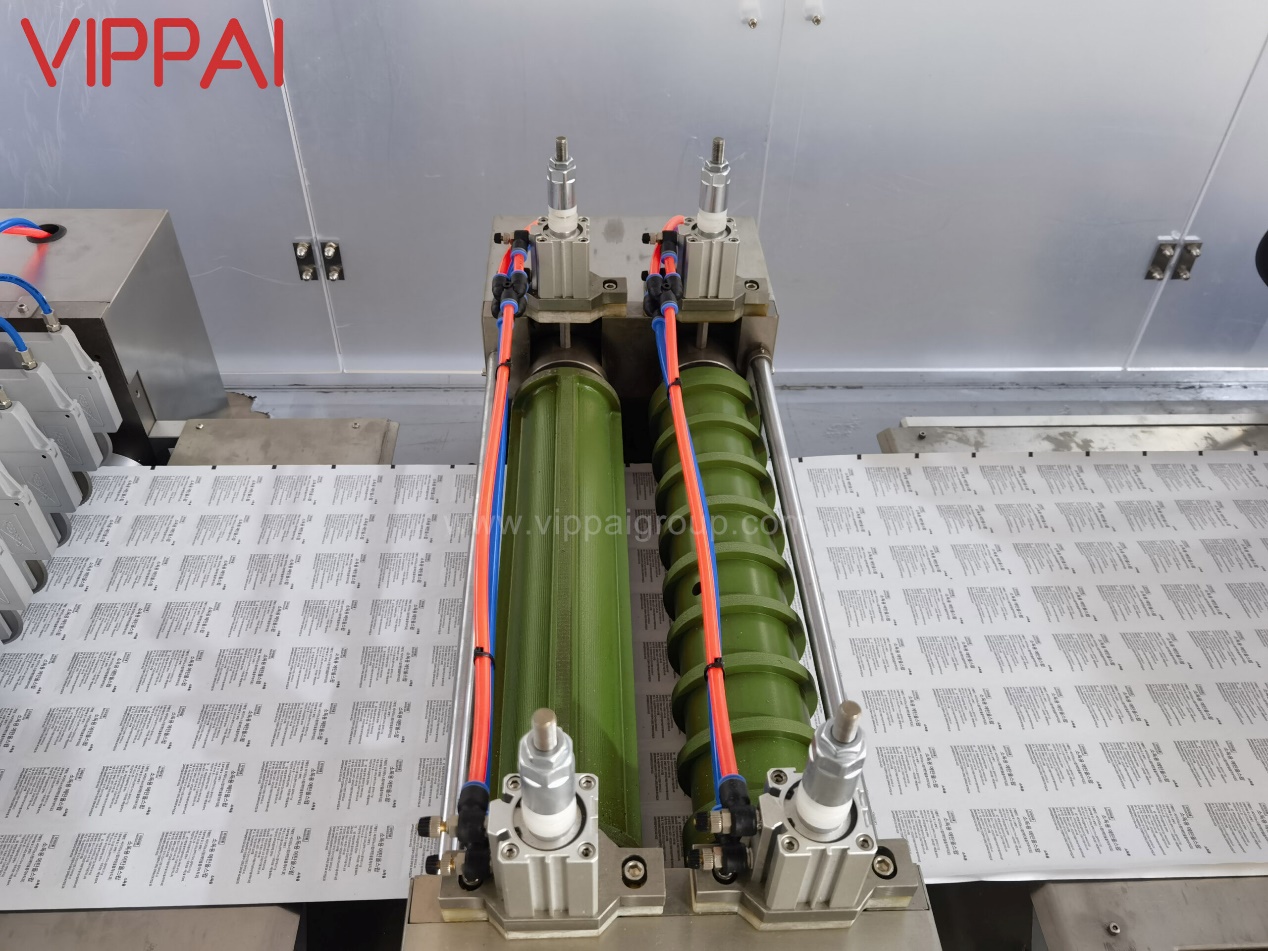

One of the standout features of our Vippai alcohol pad manufacturing machine is its versatility. The VPD-800 can automatically cut one large roll into 8 smaller rolls or utilize 8 separate non-woven rollers, enabling simultaneous production on 8 lines. This multi-line capability is a game-changer for businesses looking to maximize output without compromising quality.

By allowing simultaneous production, our pad manufacturing machine significantly boosts productivity, making it ideal for high-demand environments. Clients can efficiently scale their operations to meet market needs, ensuring that they stay competitive in an ever-evolving landscape.

Superior Components for Enhanced Performance

The VPD-800A High-Speed Multi-line Alcohol Pad/Swab Machine also features a four-side sealing packing machine equipped with a Swiss Gotec Electromagnetic Pump. This pump is known for its high accuracy and robust corrosion resistance capabilities, making it a reliable choice for alcohol pad production.

The use of high-quality components ensures that our pad manufacturing machine operates smoothly, reduces downtime, and minimizes maintenance costs. Clients can trust that our technology will deliver consistent results while adhering to the stringent hygiene standards required in the medical and pharmaceutical industries.

Conclusion

In summary, Vippai is at the forefront of innovation in alcohol pad manufacturing with our VPD-800A High-Speed Multi-line Alcohol Pad/Swab Machine. With intelligent operation, versatile production capabilities, and superior components, our pad manufacturing machine is designed to meet the highest standards of efficiency and quality. As we continue to support our clients in the medical and pharmaceutical sectors, we remain committed to providing solutions that enhance productivity and ensure compliance with industry regulations. Choose Vippai for your alcohol pad production needs and experience the difference that advanced technology can make in your operations.