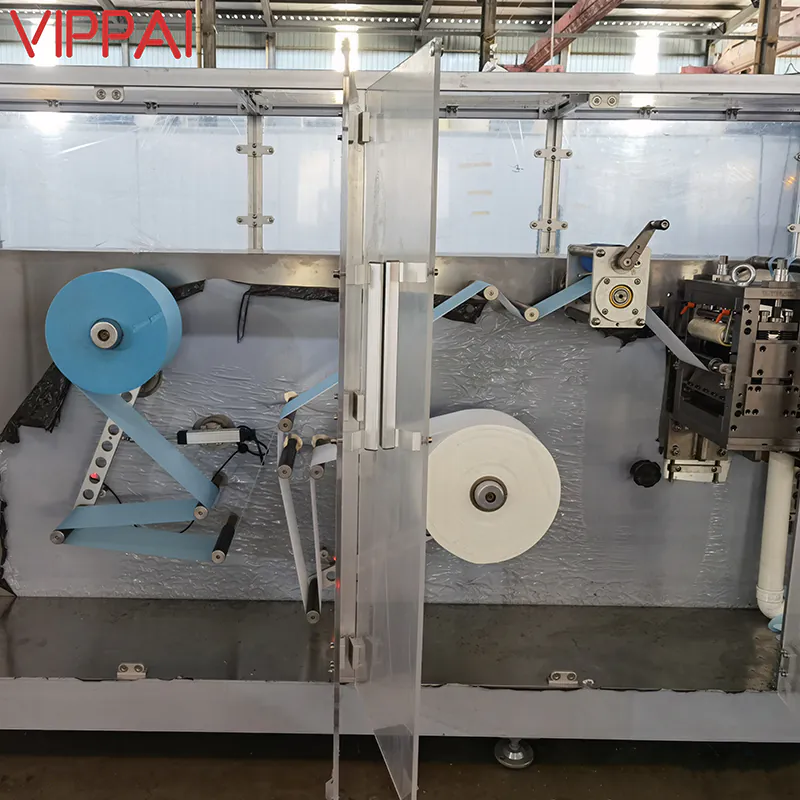

You have arrived at Vippai, the epicenter of accuracy and innovation in the eye patch manufacturing industry. The state-of-the-art features offered by our VPD300E Eye Pad Making Machine revolutionize production methods and improve the quality of your eye patches. Businesses seeking to improve their production skills might find what they need with the VPD300E, which is built with an emphasis on efficiency and dependability.

Superior Sealing Performance with Reciprocating Heat Sealing Mechanism

At Vippai, we take pride in the advanced technology integrated into our VPD300E sealing and cutting machine. The reciprocating heat sealing mechanism sets this machine apart, providing ample time for large-area sealing. This results in strong, smooth, and visually appealing seals that can accommodate a wide range of materials. With the VPD300E, you can trust in the quality and durability of every seal produced.

Enhanced Safety and Stability with Automatic Calibration and Alarm Systems

Safety and stability are paramount in the manufacturing process, and the Vippai VPD300E Eye Pad Making Machine excels in this aspect. Our machine includes an alarm system for film shortages, ensuring uninterrupted production runs. Additionally, the automatic stop capabilities and two-point cursor tracking automatic calibration correct deviations promptly, guaranteeing a safe and stable production environment. With the VPD300E, you can focus on efficiency without compromising on safety.

Versatile Packaging Capabilities for Adaptability and Convenience

The Vippai sealing and packing machine epitomizes a blend of versatility and convenience tailored for packaging operations. Engineered with rapid and hassle-free mold switching features, our machine streamlines the process of transitioning between distinct packaging specifications effortlessly. This innate adaptability positions our eye mask making machine as a versatile solution that harmonizes with an array of materials and packaging prerequisites, empowering businesses to adeptly cater to a spectrum of customer demands with utmost efficiency and precision. The seamless integration of diverse materials and packaging requirements underscores the machine's capability to flexibly adapt to evolving market dynamics, solidifying its standing as a reliable and indispensable asset for businesses seeking operational excellence in the packaging industry.

Conclusion

In conclusion, the Vippai VPD300E Eye Pad Making Machine is a testament to our commitment to innovation and excellence in the manufacturing industry. With its superior sealing and cutting capabilities, advanced safety features, and versatile packaging options, this machine is a valuable asset for businesses looking to enhance their production line efficiency. Invest in the VPD300E and experience a new level of productivity and quality in eye patch manufacturing.