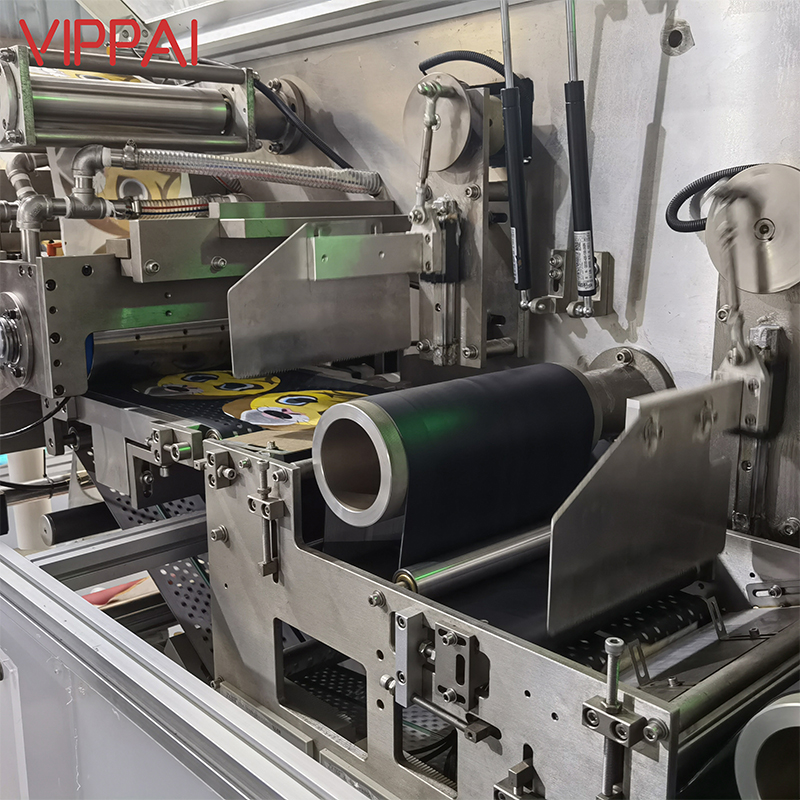

Providing innovative solutions that change the skincare manufacturing landscape is our main focus at Vippai. Producing and packaging face masks has never been easier than with our VPD-400 Face Sheet Mask Machine. It has several advantages that boost productivity and quality. This innovative face pack-making machine minimizes labour requirements, ensures contamination-free production, and adheres to the highest industry standards. Let’s delve into the key advantages of the VPD-400 and how it can transform your business.

Streamlined Production Processes

One of the most significant benefits of the VPD-400 face mask sheet making machine is its ability to automate mask production and packaging. By integrating the entire process into one machine, we eliminate the need for 8-15 manual workers, significantly streamlining production processes. This reduction in labor not only helps businesses cut costs but also allows teams to focus on more strategic activities, such as product innovation and marketing. With the VPD-400, we empower our clients to maximize their productivity and efficiency in a competitive market.

Controlled Environment for Quality Assurance

Ensuring the highest quality of face sheet masks is crucial for consumer safety and satisfaction. The VPD-400 operates within a controlled environment, which is essential for maintaining hygiene standards and preventing contamination during the production process. By utilizing this face pack making machine, businesses can have peace of mind knowing that every mask produced is free from impurities. This meticulous attention to detail not only enhances product quality but also builds trust with consumers, reinforcing brand loyalty.

Compliance with GMP Standards

In the skincare industry, adhering to regulatory standards is non-negotiable. The Vippai VPD-400 fully complies with GMP (Good Manufacturing Practice) certification requirements, making it a reliable choice for businesses that prioritize quality and safety. This commitment to compliance means that our clients can confidently market their face masks, knowing they meet the rigorous standards set forth by health authorities. By investing in the VPD-400, we help our clients maintain their reputation for excellence while navigating the complexities of regulatory compliance.

Cost Savings on Labor and Materials

Another compelling advantage of the automatic bag filling machine VPD-400 is its ability to save on labor costs and reduce packaging material expenses by 20-30%. By automating the face pack making process, businesses can allocate resources more efficiently, allowing for better budget management and cost control. These savings can be reinvested into other areas of the business, such as research and development or marketing initiatives. Ultimately, the VPD-400 provides a more sustainable approach to manufacturing, benefiting both the bottom line and the environment.

Conclusion:

In conclusion, the VPD-400 Face Sheet Mask Machine from Vippai offers a multitude of benefits that can significantly enhance your skincare production capabilities. With streamlined processes, a controlled production environment, compliance with GMP standards, and substantial cost savings, our face pack making machine is an invaluable asset for any cosmetics manufacturer. We are committed to helping our clients achieve operational excellence and remain competitive in the ever-evolving skincare market. Choose Vippai and elevate your face mask production to new heights today!