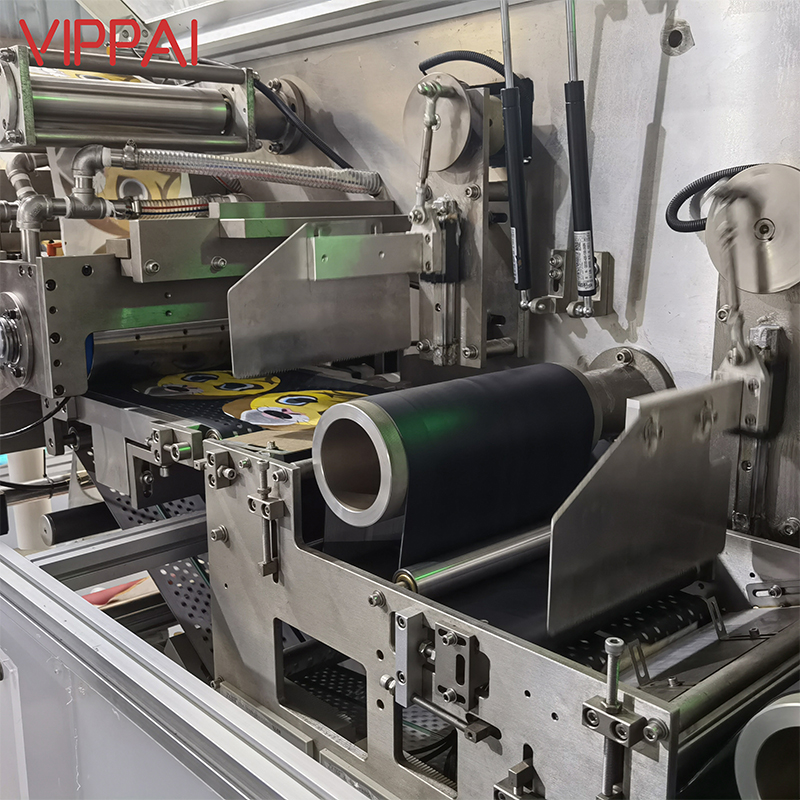

Using our cutting-edge packaging solutions, Vippai is committed to transforming the skincare and cosmetics industries. Our VPD-400 Face Mask Sheet Machine is designed to streamline the production of face masks while ensuring the highest standards of quality and hygiene. This advanced face mask sheet machine brings multiple benefits that enhance manufacturing efficiency and reduce operational costs, making it an essential tool for modern production lines.

Streamlined Production Processes

One of the standout benefits of the VPD-400 face mask sheet machine is its ability to eliminate the need for 8-15 workers in the production process. By automating mask production packaging, we significantly streamline operations and enhance overall efficiency. This reduction in labor not only cuts down on operational costs but also minimizes the likelihood of human error, ensuring that each step of the production process is executed with precision.

Our commitment to efficiency means that our partners can focus their workforce on other critical areas of their business, maximizing productivity and allowing for growth without the need for extensive hiring.

Controlled Environment for Quality Assurance

Quality and hygiene are paramount in the production of cosmetic products. The entire production process of the VPD-400 face mask sheet machine is conducted within a controlled environment, ensuring that the face sheet mask packaging is free from contamination. This meticulous attention to detail helps maintain the integrity of the masks, ensuring they meet the high standards expected by consumers.

By minimizing the risk of contamination, we provide our partners with peace of mind, knowing that their products are being manufactured in a safe and sterile environment. This focus on quality assurance is crucial for building trust with consumers and enhancing brand reputation.

Compliance with GMP Standards

Our VPD-400 face mask sheet machine fully complies with GMP (Good Manufacturing Practice) certification requirements. This adherence to industry standards demonstrates our commitment to producing high-quality products that are safe for consumers. The machine is designed to meet stringent regulatory requirements, which is essential for brands looking to maintain compliance in the ever-evolving cosmetics landscape.

By choosing a machine that complies with GMP standards, our partners can confidently market their products, knowing they meet the rigorous safety and quality benchmarks set by the industry.

Cost Savings on Labor and Materials

In addition to improving labor efficiency, the VPD-400 face mask sheet machine also offers substantial savings on packaging material expenses. Our automatic bag filling machines can reduce these costs by 20-30%, making it an economically sound investment for manufacturers.

These cost savings arise from the machine's efficient use of materials and streamlined production processes, allowing brands to allocate their resources more effectively. By reducing both labor and material costs, we help our partners improve their bottom line while maintaining high-quality production standards.

Conclusion

At Vippai, we are proud to offer the VPD-400 Face Mask Sheet Machine, a cutting-edge solution that enhances efficiency and quality in the production of face masks. With benefits such as streamlined production processes, a controlled manufacturing environment, compliance with GMP standards, and significant cost savings, our face mask sheet machine is designed to meet the needs of modern manufacturers. By partnering with Vippai, you are investing in a future of innovation, quality, and operational excellence. Together, let’s elevate your production capabilities and set new benchmarks in the beauty industry.