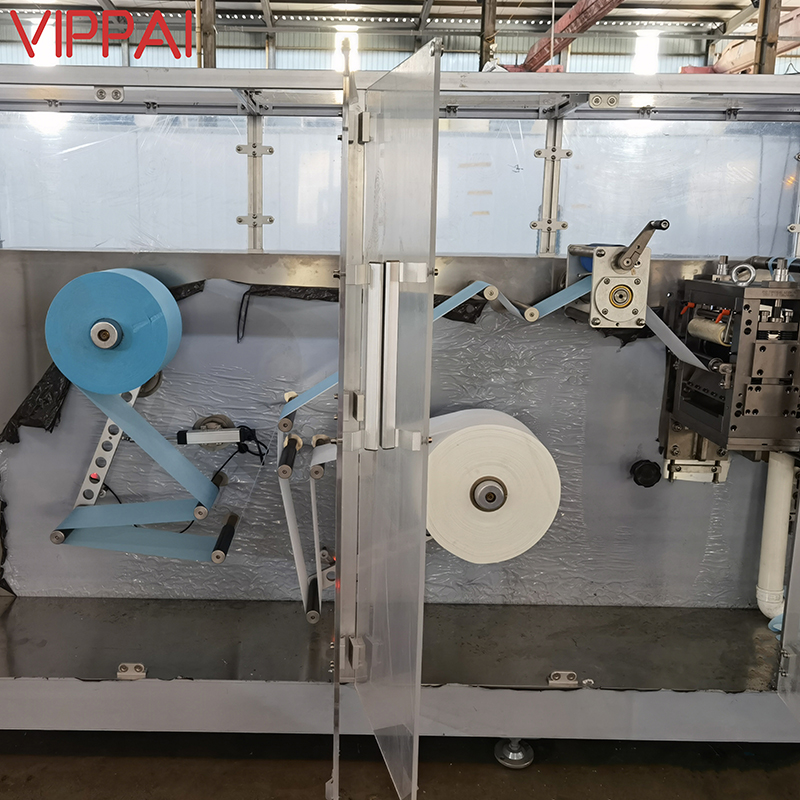

Here at Vippai, we're dedicated to changing the manufacturing industry with our innovative solutions. Our VPD300E eye mask making machine exemplifies this commitment, offering an array of benefits that enhance production efficiency and product quality. As a leading sealing and packing machine, the VPD300E is designed to meet the diverse needs of the cosmetics industry. In this article, we will delve into the features that make the VPD300E an essential tool for your eye patch production line.

Simple and Reliable Operation

One of the standout features of the VPD300E eye mask making machine is its incorporation of a Japanese Yaskawa servo motor. This advanced motor ensures that parameter adjustments are simple, safe, and reliable, all managed through an intuitive touchscreen interface. We recognize that user experience is crucial for operational efficiency, and our machine's design reflects this understanding. By making it easy for operators to adjust settings on the fly, we enable businesses to respond quickly to production demands without compromising on safety or quality.

Superior Sealing Capabilities

The Vippai sealing and packing machine is equipped with a reciprocating heat sealing mechanism, which allows ample time for large-area sealing. This feature is particularly beneficial for creating strong, smooth, and aesthetically pleasing seals that accommodate a variety of materials. We understand that the visual appeal of packaging plays a significant role in consumer choice, and our machine ensures that your eye patches stand out on the shelves. With robust sealing capabilities, businesses can trust that their products will not only remain secure but also look attractive to potential customers.

Enhanced Safety Features

Safety is a top priority in any manufacturing environment. The VPD300E eye mask making machine includes an alarm for film shortages and automatic stop capabilities, ensuring that production halts when issues arise. Additionally, the machine employs a two-point cursor tracking automatic calibration system, which corrects deviations to maintain safety and stability during operation. We believe that ensuring the safety of both the product and the operators is essential, and our machine is designed to minimize risks while maintaining productivity.

Versatile and Adaptable Design

Another significant advantage of the Vippai sealing and packing machine is its versatile packaging capabilities. The VPD300E facilitates fast and convenient mold switching, making it highly adaptable to various packaging specifications. This flexibility allows businesses to diversify their product offerings without extensive downtime or reconfiguration. Whether you are producing different sizes or types of eye masks, our machine can accommodate your needs, enhancing your production line's efficiency and reliability.

Conclusion:

In conclusion, the VPD300E eye mask making machine from Vippai is a powerful asset for any business in the cosmetics industry. With its simple operation, superior sealing capabilities, enhanced safety features, and versatile design, our sealing and packing machine stands out as a reliable solution for eye patch production. We are excited to help businesses optimize their manufacturing processes and achieve higher levels of efficiency and quality. Join us at Vippai and discover how our innovative solutions can elevate your production line today!