In the competitive landscape of consumer goods, where product integrity and shelf appeal are paramount, the importance of efficient and reliable packaging cannot be overstated. Sealing and packing not only protect the product from external contaminants but also significantly enhance its marketability and user satisfaction. Let's explore why sealing and packing are vital components of successful packaging strategies and how Vippai's VPD300E Eye Patch Making Machine stands out as a leader in sealing and packing machine.

Why is Effective Sealing and Packing Essential?

Product Protection

The primary purpose of sealing and packing is to protect the product from environmental factors such as moisture, dust, and other contaminants. This protection is crucial for maintaining the product's quality and longevity, especially for items that are sensitive, like skincare products.

Tamper Evidence

Proper sealing helps in providing tamper evidence, an essential feature for consumer safety. This reassurance is particularly crucial in industries like pharmaceuticals and cosmetics, where product integrity directly impacts user health.

Shelf Life Extension

Sealing and packing technologies can significantly extend a product's shelf life by creating a barrier against external agents. This is especially important for perishable goods, including food and certain organic cosmetic products.

Brand Image and Consumer Appeal

Well-designed and efficiently sealed packages enhance the product's aesthetic appeal, which can strongly influence buyer decisions. A good packaging design, supported by superior sealing quality, can make a product stand out on the shelves and reinforce brand identity.

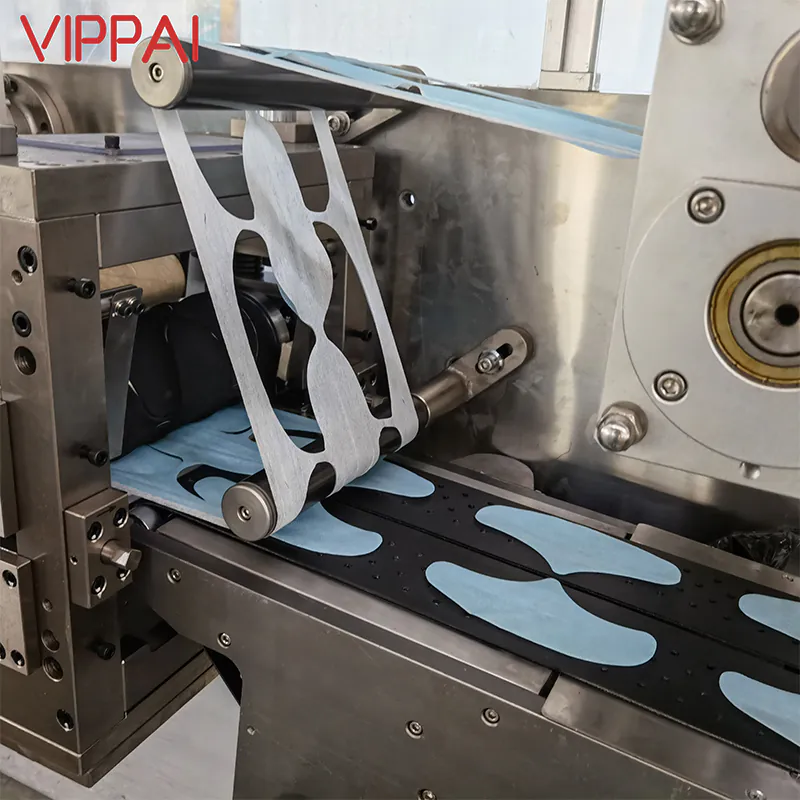

Introducing Vippai's VPD300E Eye Pad Making Machine

Vippai's VPD300E Eye Patch Making Machine is at the forefront of sealing and packing technology, specifically designed for the efficient production of non-woven material eye patches. This machine integrates cutting-edge features that cater to the growing demands of the cosmetics industry.

High-Speed Production

The VPD300E operates at an impressive rate of 80-120 bags per minute, making it one of the fastest machines in its class. This high-speed functionality ensures that large orders can be fulfilled quickly and efficiently, keeping your business responsive to market needs.

Advanced Sealing Technology

Utilizing advanced four-side sealing technology, the VPD300E guarantees that each eye patch is sealed with precision. This technology not only enhances the safety and durability of the packaging but also ensures that each product meets the high standards expected by consumers today.

Customization Options

Understanding that different markets may have varying requirements, the VPD300E offers extensive customization options. Whether it's adjusting the size, shape, or type of eye patches, this machine provides the flexibility needed to cater to diverse consumer preferences and emerging market trends.

Designed for Non-Woven Materials

Specifically engineered for non-woven fabric eye patches, the VPD300E ensures that the delicate materials are handled with care throughout the production process. This consideration is crucial for maintaining the efficacy and quality of the final product.

Ideal for Automation

For businesses aiming to automate their eye patch production, the VPD300E represents a perfect solution. It combines reliability with versatility, making it an invaluable asset for companies looking to enhance their production capabilities and efficiency.

Conclusion

Effective sealing and packing are indispensable for maintaining product quality, extending shelf life, and enhancing consumer appeal. Vippai's VPD300E Eye Patch Making Machine exemplifies the best in sealing and packing technology, tailored specifically for the cosmetic industry's needs. Investing in such advanced machinery is not just about automating production; it's about committing to quality, efficiency, and consumer satisfaction. The VPD300E is more than a machine; it's a cornerstone for any cosmetic business aiming to thrive in a competitive market.