Welcome to Vippai, your trusted partner in eye patch manufacturing. Today, we are excited to introduce our innovative VPD300E Eye Patch Making Machine. Designed to integrate production and packaging seamlessly, this machine revolutionizes the eye patch manufacturing process. With customizable essence-adding device options and a focus on non-woven material eye patches, the VPD300E offers versatility and efficiency. In this article, we will explore the key features of this machine, including its high-speed production capabilities and adoption of four-side sealing technology. Join us as we dive into the world of Vippai's Patch Manufacturing Machine, enhancing your eye patch production from start to finish.

Customizable Essence-Adding Device for Personalized Eye Patches

Vippai's VPD300E Patch Manufacturing Machine allows for the incorporation of various essence-adding devices during the eye patch production process. This unique feature enables manufacturers to cater to different skincare needs and preferences by customizing the ingredients or treatments in their eye patches. Whether it's rejuvenating serums, soothing extracts, or hydrating essences, the essence-adding device options offer endless possibilities for creating personalized eye patches. With Vippai's Patch Manufacturing Machine, businesses can stand out in the market and meet the diverse demands of their customers.

Non-Woven Material Eye Patch Production for Enhanced Comfort

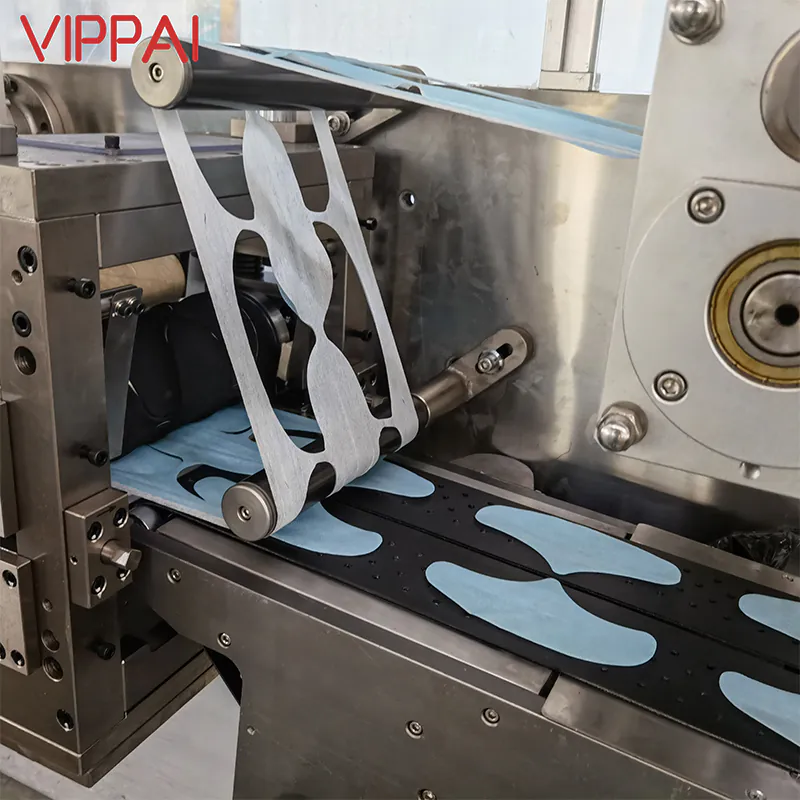

In the eye patch market, two primary materials dominate: non-woven and gel. The VPD300E Patch Manufacturing Machine specializes in producing high-quality non-woven material eye patches. Non-woven eye patches are known for their lightweight, breathable, and comfortable characteristics, making them a popular choice among consumers. By focusing on non-woven material eye patches, businesses using Vippai's machine can meet market demands and provide customers with eye patches that offer superior comfort and wearability.

High-Speed Production and Four-Side Sealing Technology

The VPD300E Patch Manufacturing Machine boasts impressive production speeds, ranging from 80 to 120 bags per minute. This high-speed capability allows manufacturers to meet tight deadlines, handle large production volumes, and stay ahead of market demands. Additionally, the machine adopts four-side sealing technology, ensuring secure and tamper-proof packaging for the eye patches. The four-side sealing technique enhances product integrity, preventing contamination and preserving the freshness of the eye patches. With Vippai's Patch Manufacturing Machine, businesses can achieve efficient production and deliver eye patches that are impeccably sealed for customer satisfaction.

Conclusion:

In conclusion, Vippai's VPD300E Patch Manufacturing Machine revolutionizes the production of non-woven material eye patches. With its customizable essence-adding device options, high-speed production capabilities, and utilization of four-side sealing technology, this machine sets new standards for efficiency and quality. By seamlessly integrating production and packaging processes, businesses can optimize their operations and deliver exceptional eye patches that cater to specific skincare needs. Join the Vippai family and experience the benefits of our advanced Patch Manufacturing Machine, designed to elevate your eye patch production from start to finish.