In the competitive world of cosmetics and skincare production, efficiency and quality are the pillars of success. For businesses aiming to enhance their production capabilities while adhering to the highest standards, Vippai's VPD-400 Face Sheet Mask Machine represents a transformative solution. This article post explores why Vippai's automatic bag filling machine is the trusted choice for leading brands worldwide and how it can elevate your production process.

Advanced Automation in Packaging

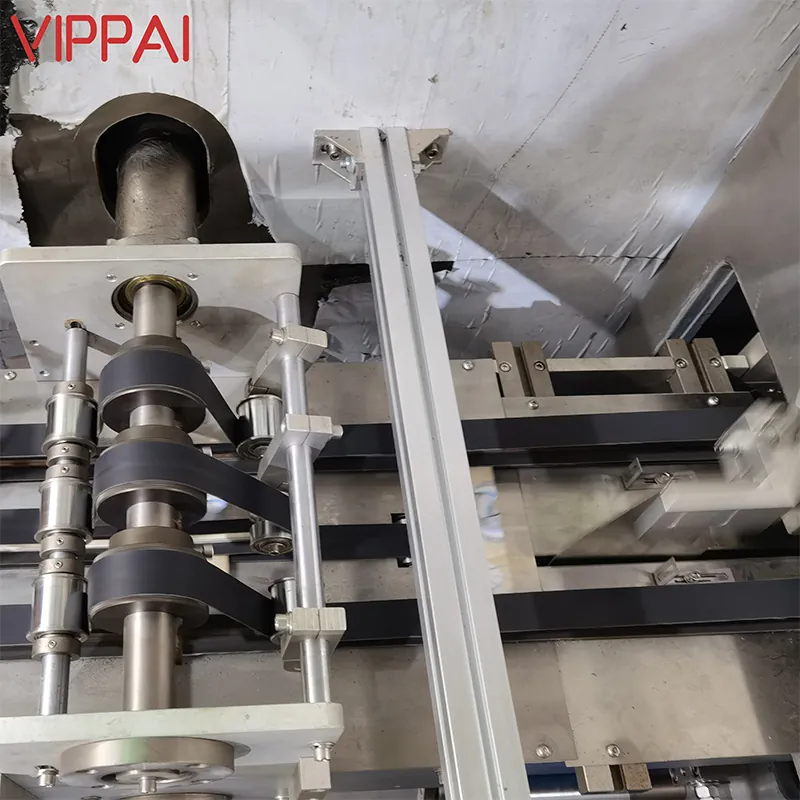

The VPD-400 is not just an automatic bag filling machine; it's a comprehensive solution for the face sheet mask industry. Designed to handle everything from roll film feeding to bag sealing, this machine incorporates all necessary actions to deliver a finished product that meets the exacting standards of the cosmetic industry. The integration of multiple processes into one machine not only streamlines production but also significantly enhances output efficiency.

Comprehensive Process Integration

The process starts with roll film feeding and encompasses testing, film cutting and forming, mask folding, and online bag making—or using pre-made bags—before adding liquid essence and sealing the bags. By automating these steps, the VPD-400 minimizes human error and maximizes consistency and quality, ensuring that every product meets pharmaceutical-grade GMP production standards.

Reducing Labor and Space Requirements

One of the most significant advantages of the VPD-400 is its impact on labor and space economy. By replacing several traditional manual workshop machines, such as punching, forming, folding, filling, and sealing machines, this automatic packing machine cuts labor needs by 8-15 workers. Additionally, it optimizes workshop space usage, allowing businesses to utilize their production areas more efficiently or reduce overhead costs associated with larger spaces.

Addressing Secondary Pollution

In the production of cosmetics, particularly skincare items like face sheet masks, maintaining a sterile environment is crucial. The VPD-400 addresses common issues of secondary pollution that occur during production processes. By automating the production and packaging within a controlled setting, this machine ensures that each mask is free from contaminants, thus safeguarding product integrity and consumer trust.

Trusted by Global Brands

The reliability and effectiveness of the VPD-400 are not just claims; they are proven by partnerships with major cosmetic brands globally. Esteemed clients such as Korea's Mediheal, JAYJUN Cosmetic, New Zealand's Essano, US-based Yesto, Poland's Marion Sp. z o.o, and the UK's Egg Cream Mask are testament to the machine's capabilities and the trust it has earned in the industry.

Why Choose Vippai's VPD-400?

Investing in Vippai's VPD-400 automatic bag filling machine means choosing a partner known for innovation and reliability in the cosmetic manufacturing industry. Here's why Vippai stands out:

Pharmaceutical-grade GMP Production Standards: Each machine is designed to meet rigorous health and safety standards, ensuring your products are manufactured in a pristine environment.

Complete Process Control: From start to finish, control every aspect of the production process, reducing variability and ensuring a high-quality end product.

Efficiency at Scale: Achieve higher output without compromising on quality, allowing your business to grow and meet increasing market demands.

Reduced Operational Costs: Save on labor and space, reducing overall production costs and increasing profitability.

Conclusion

For cosmetic companies looking to scale up their production of face sheet masks while ensuring each item meets global quality standards, Vippai's VPD-400 Face Sheet Mask Machine is the solution. By integrating advanced technology with practical design, Vippai helps you streamline your production process, reduce costs, and maintain the highest standards of quality and hygiene. Invest in Vippai's technology and position your brand at the forefront of the cosmetic industry.