In the dynamic world of cosmetic manufacturing, the need for efficiency, reliability, and high-quality output is paramount. Vippai's cutting-edge VPD300E Eye Pad Making Machine is engineered to meet these needs, providing an advanced solution for businesses looking to enhance their production capabilities. Here's why the VPD300E stands out as a superior choice for eye patches making machine.

Key Benefits of the Vippai VPD300E Eye Mask Making Machine

- Advanced Servo Motor Technology

The VPD300E is equipped with a state-of-the-art Japanese Yaskawa servo motor, renowned for its reliability and precision. This motor enables simple and safe parameter adjustments directly via a user-friendly touchscreen interface. This feature not only enhances the machine's ease of use but also ensures consistent quality in the production process, making it accessible to operators of all skill levels.

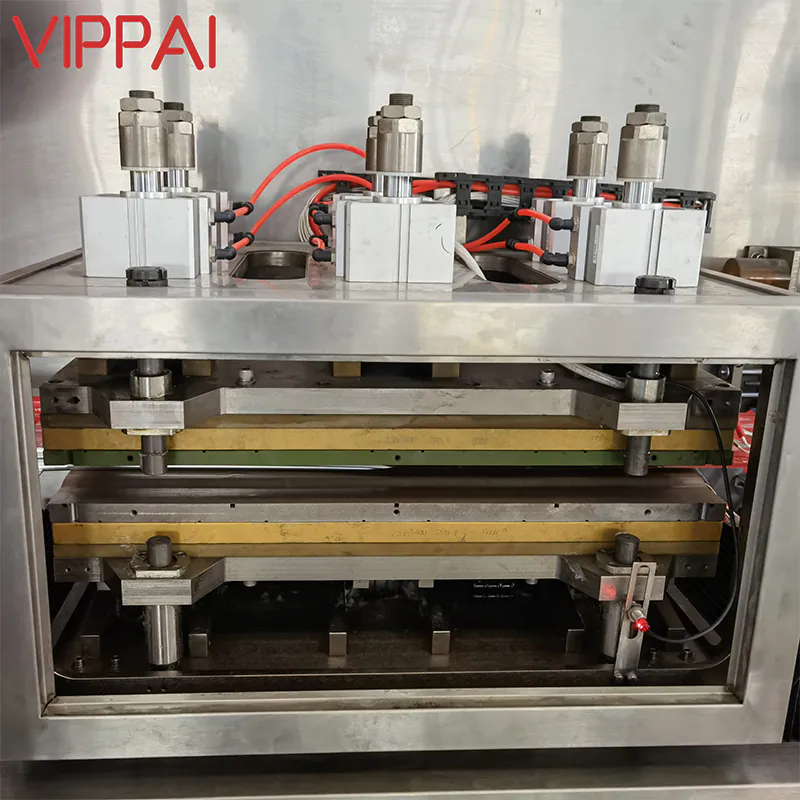

- Optimized Sealing Mechanism

Our machine features a unique reciprocating heat sealing mechanism. This design allows more time for sealing each patch, which is crucial for achieving strong, smooth, and visually appealing seals. The ability to handle large-area sealing efficiently makes the VPD300E exceptionally suitable for a variety of materials, ensuring that each product meets the high standards expected in the cosmetics industry.

- Enhanced Safety and Stability Features

Safety and stability in manufacturing are non-negotiable. The VPD300E addresses these concerns head-on with integrated safety features such as an alarm system for film shortages and automatic stop capabilities. Additionally, the machine includes a two-point cursor tracking automatic calibration system that corrects deviations, further ensuring the reliability and consistency of the production process.

- Versatile Packaging Capabilities

Flexibility in packaging is crucial for businesses that cater to diverse market demands. The VPD300E excels in this area by facilitating fast and convenient mold switching. This adaptability allows the machine to be quickly configured to meet various packaging specifications, making it highly compatible with different product designs and sizes. Whether you are producing standard or custom eye patches, the VPD300E can be adjusted to meet your specific needs efficiently.

Ideal for Growing and Established Businesses

The VPD300E Eye Pad Making Machine is not just a piece of equipment; it's a comprehensive solution designed to streamline the production of eye patches. From startups aiming to penetrate the market with innovative products to established businesses looking to scale up their operations, the VPD300E provides the tools necessary to achieve production goals with ease and precision.

Conclusion

Vippai's VPD300E Eye Pad Making Machine is more than just a technological advancement—it is a strategic asset for any cosmetics manufacturer. With its combination of advanced motor technology, optimized sealing capabilities, robust safety features, and versatile packaging options, the VPD300E sets new standards in the industry. By investing in this machine, businesses can look forward to not only meeting but exceeding their production expectations, enhancing product quality, and ultimately satisfying customer needs more effectively.