Here at Vippai, we're dedicated to helping the skincare and cosmetics industries stay ahead of the curve. Our VPD-400 Face Sheet Mask Machine is an advanced automatic face sheet mask packaging solution designed to manufacture and package sheet masks efficiently. This innovative automatic bag filling machine adheres to pharmaceutical-grade GMP production standards, ensuring the highest quality at every step of the process.

Comprehensive Production Process

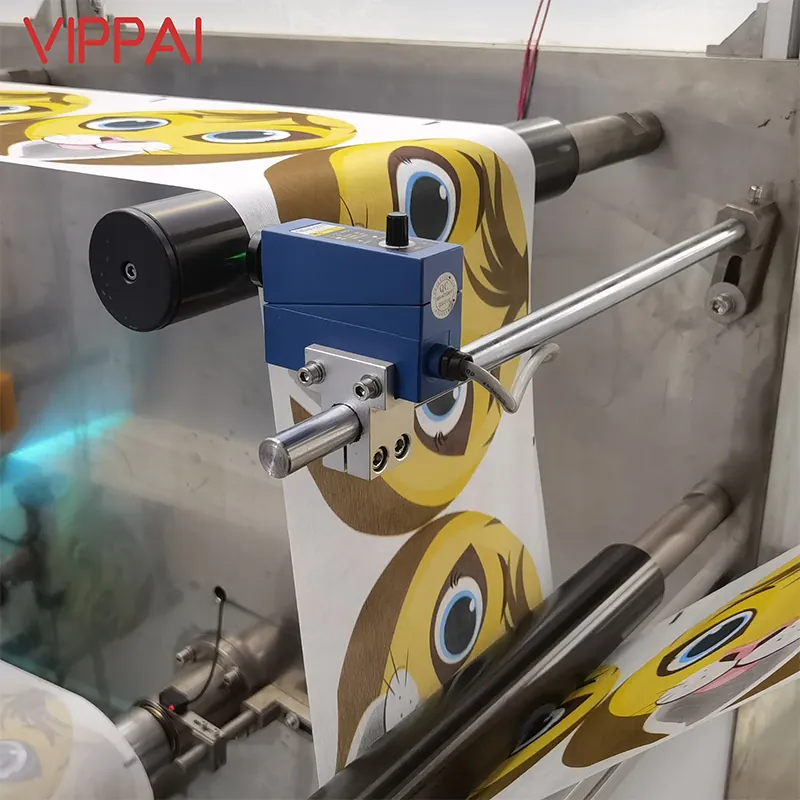

The VPD-400 automatic bag filling machine is engineered to handle a wide range of processes, from roll film feeding to testing, film cutting and forming, mask folding, online bag making, liquid essence addition, sealing, and more. This comprehensive production capability means that manufacturers can streamline their operations significantly.

By integrating multiple functions into one machine, we eliminate the need for several separate pieces of equipment. This not only enhances efficiency but also simplifies the production line, making it easier for operators to manage and oversee the entire process. Our automatic bag filling machine ensures that each step is executed with precision, resulting in high-quality face sheet masks that meet consumer expectations.

Reducing Labor and Space Requirements

One of the significant advantages of the VPD-400 face pack making machine is its ability to replace traditional manual workshop equipment such as punching machines, forming machines, folding machines, filling machines, and sealing machines. By consolidating these functions into a single automated solution, we help our clients reduce labor requirements by 8-15 workers.

This reduction in labor not only cuts operational costs but also minimizes the amount of workshop space needed for production. Our automatic bag filling machine is designed to optimize space utilization, allowing businesses to focus their resources on other critical areas. This efficient use of space and manpower means that manufacturers can increase their output without the need for extensive investment in additional equipment or facilities.

Addressing Quality and Hygiene Concerns

At Vippai, we understand the importance of quality and hygiene in the production of cosmetic products. The VPD-400 face sheet mask machine effectively addresses secondary pollution issues during production, ensuring that the masks are produced in a clean and controlled environment. Adhering to pharmaceutical-grade GMP standards, our automatic bag filling machine is designed to maintain the highest levels of hygiene, safeguarding the integrity of the final product.

Moreover, the versatility of the VPD-400 allows for both online bag making and the use of pre-made bags, providing flexibility to our clients based on their specific production needs. This adaptability, coupled with our commitment to quality, has made us a trusted partner for renowned brands like Korea Mediheal, JAYJUN Cosmetic, New Zealand Essano, US Yesto, Poland Marion Sp. z o.o, and UK Egg Cream Mask.

Conclusion

At Vippai, we are proud to lead the way in innovative packaging solutions for the cosmetics and skincare industries. Our VPD-400 Face Sheet Mask Machine is a game-changer, combining advanced technology with efficiency and reliability. By investing in our automatic bag filling machine, manufacturers can streamline their production processes, reduce labor and space requirements, and ensure the highest quality in their products. Together, let’s elevate your packaging operations and set new standards in the beauty industry.