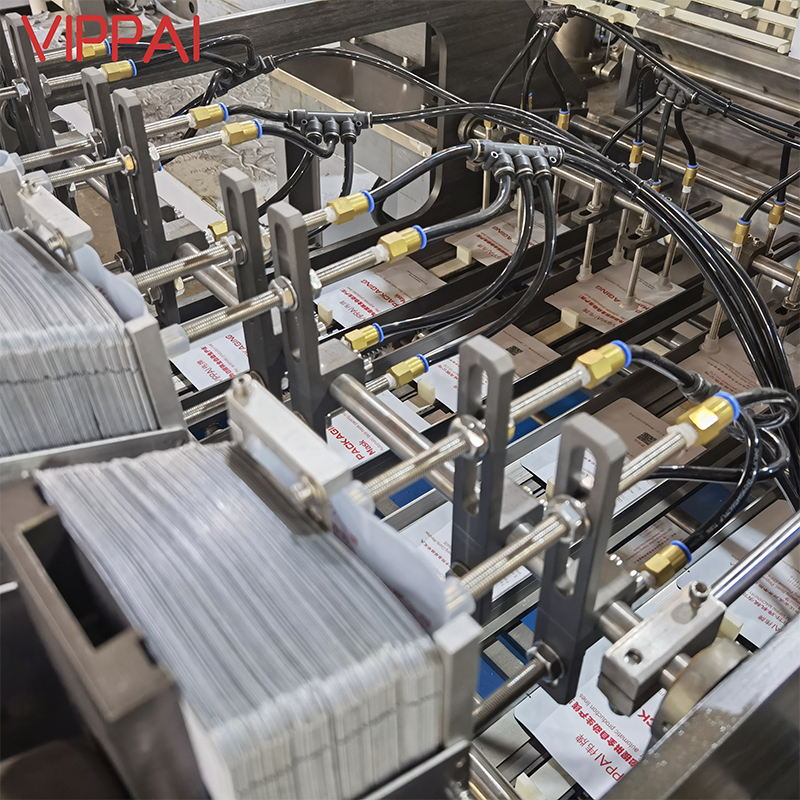

At Vippai, we are proud to introduce the Vippai VPD98-4 Cosmetics Face Mask Packaging Machine—a advanced solution that redefines efficiency and precision in facial mask packaging. With a focus on user-friendly design and cutting-edge technology, this machine is set to elevate your cosmetic production processes to new heights. Join us as we explore the advanced features and benefits of the Vippai VPD98-4, tailored to meet the demands of modern facial mask packaging.

Enhanced Stability and User-Friendliness:

The automated face mask packing machine features adjustable servo settings that enhance stability and user-friendliness. By allowing users to customize settings according to their specific needs, the Vippai VPD98-4 ensures a smooth and precise packaging process. This focus on user convenience not only improves operational efficiency but also reduces the learning curve for operators, making it an ideal choice for businesses seeking a seamless packaging solution.

Safety and Reliability in Design:

Designed with a separate balcony for the drive and workstations, the Vippai cosmetic mask packing machine ensures both safety and operational reliability. This thoughtful design feature not only enhances workplace safety by creating a clear separation between different components but also improves accessibility for maintenance and troubleshooting. By prioritizing safety and reliability, Vippai demonstrates a commitment to creating a machine that meets the highest industry standards.

Precision Filling Capabilities:

Utilizing a high-end metering pump, the Vippai beauty mask packing machine achieves precise filling accuracy within a tolerance of ±1 gram. This level of accuracy is crucial in cosmetic production, where consistency is key to delivering high-quality products. The Vippai VPD98-4's advanced metering pump technology ensures that each mask is filled with the exact amount of product, guaranteeing uniformity and quality in every package.

Adherence to Quality Standards:

The entire automated face mask packaging machine is fully compliant with GMP certification requirements, guaranteeing adherence to rigorous standards of production quality and hygiene. By meeting GMP standards, Vippai ensures that every step of the packaging process follows best practices for cleanliness, traceability, and quality control. This commitment to excellence underscores Vippai's dedication to delivering reliable and safe packaging solutions for the cosmetic industry.

Conclusion:

In conclusion, the Vippai VPD98-4 Cosmetics Face Mask Packaging Machine is a game-changer in the world of facial mask packaging. Its innovative features, including adjustable servo settings, separate workstations for safety, precision filling capabilities, and GMP compliance, set a new standard for efficiency and quality in cosmetic production. By incorporating the Vippai VPD98-4 into your production line, you can streamline your packaging processes, enhance product consistency, and ensure compliance with industry regulations.

Take your facial mask packaging to the next level with the Vippai VPD98-4—a machine designed to optimize your workflow, improve operational reliability, and deliver exceptional results. Experience the future of cosmetic production with Vippai and unlock a world of possibilities for your brand.