At Vippai, we understand the importance of quality and safety in the production of facial masks. Our face mask packaging machine is designed to meet the high standards required to protect product integrity throughout the manufacturing process. In this article, we will discuss how our machine operates within a controlled environment to maintain the purity of the masks and prevent contamination.

Controlled Environment for Optimal Purity

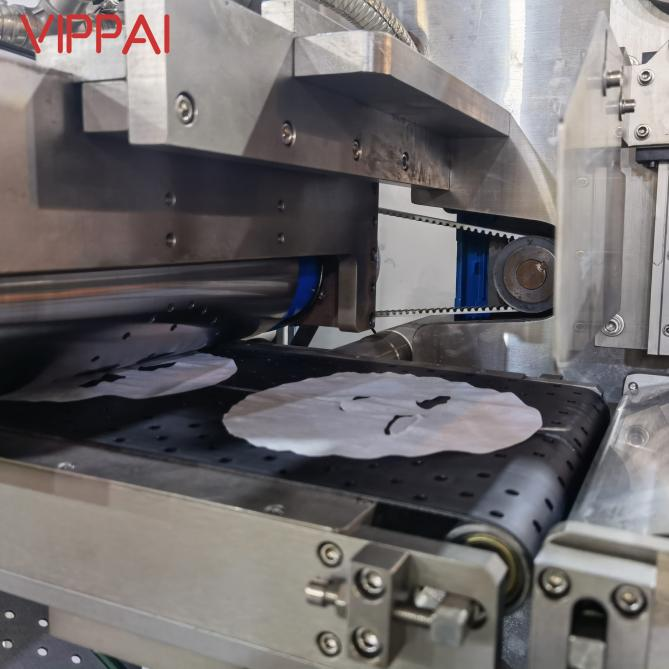

One of the key features of our face mask packaging machine is its ability to operate in a controlled environment. We recognize that facial masks are often used for sensitive skin and must be free from contaminants. By implementing strict environmental controls during the packaging process, we ensure that every mask is produced in a clean and sterile setting. This minimizes the risk of contamination and preserves the quality of the product, giving consumers peace of mind.

Advanced Technology for Precision

Our face mask packaging machine utilizes advanced technology that allows for precise filling, sealing, and packaging of facial masks. We have integrated cutting-edge sensors and automation to ensure that each step of the process is executed with accuracy. This technology not only enhances efficiency but also guarantees that the masks are packaged securely, reducing the likelihood of defects or spoilage.

Streamlined Production Process

At Vippai, we aim to streamline production processes to enhance productivity. The face mask packaging machine is designed for high-speed operations, allowing manufacturers to meet increasing market demands without compromising quality. With the ability to produce a high volume of masks in a short time, we help our clients stay competitive in the ever-evolving beauty industry.

User-Friendly Operation

We believe that efficiency should go hand in hand with ease of use. Our face mask packaging machine features an intuitive control interface that allows operators to easily adjust settings and monitor production. This user-friendly design minimizes the learning curve for new staff and helps maintain consistent production quality. With our machine, even those new to the industry can quickly become proficient in operating it.

Commitment to Quality Control

Quality control is at the forefront of our mission at Vippai. Each face mask packaging machine is built to comply with industry standards, ensuring that our clients can trust the performance and reliability of our products. Regular maintenance and updates to our technology ensure that your production remains at the highest standards over time. We are committed to supporting our clients in maintaining the quality of their products.

Conclusion

In conclusion, the Vippai face mask packaging machine is an essential tool for any manufacturer looking to produce high-quality facial masks in a safe and efficient manner. By operating within a controlled environment, utilizing advanced technology, and prioritizing user-friendly design, we ensure that every aspect of the packaging process maintains the purity of the masks and prevents contamination.

Investing in our face mask packaging machine is not just a choice for better production—it’s a commitment to quality and safety that your customers will appreciate. At Vippai, we are dedicated to helping you achieve your production goals while upholding the highest industry standards. Contact us today to learn more about how our packaging solutions can benefit your business!