At Vippai, we are passionate about transforming the skincare industry with innovative solutions that elevate production efficiency and quality. Our VPD-400 Face Sheet Mask Machine is an advanced automatic face sheet mask packaging solution designed to streamline the entire manufacturing process. Imagine a system that not only produces high-quality sheet masks but also adheres to pharmaceutical-grade GMP production standards. With our automatic bag filling machine, we handle everything from roll film feeding to testing, film cutting and forming, mask folding, and bag sealing. Let’s explore the remarkable features of the VPD-400 and how it can benefit your business.

Comprehensive Production Process

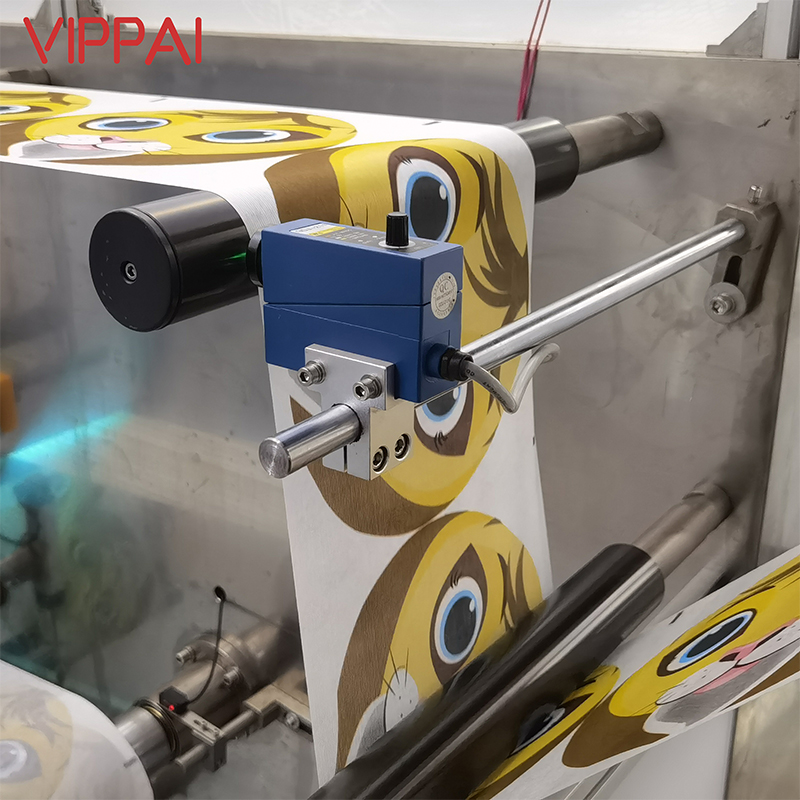

The VPD-400 is a versatile automatic bag filling machine that covers every aspect of face mask production. This includes critical processes such as liquid essence addition, online bag making (or using pre-made bags), and comprehensive testing to ensure quality control. By automating these processes, we eliminate the inconsistencies often associated with manual operations. Our machine not only enhances productivity but also guarantees the hygiene and safety of the products, adhering to strict pharmaceutical standards throughout the manufacturing cycle. This comprehensive approach allows businesses to focus on innovation and product development while we take care of the intricacies of production.

Reduced Labor and Space Requirements

One of the significant advantages of the VPD-400 is its ability to replace traditional manual workshop equipment, such as punching machines, forming machines, filling machines, and sealing machines. By integrating all these functions into one automatic bag filling machine, Vippai significantly reduces labor requirements, freeing up 8-15 workers in the production line. This reduction not only cuts costs but also minimizes the amount of workshop space needed for operations. With a more compact and efficient setup, businesses can allocate resources more effectively and streamline their production environments.

Addressing Production Challenges

In today’s competitive market, addressing production challenges is crucial for maintaining quality and customer satisfaction. The VPD-400 face pack making machine effectively tackles secondary pollution issues that can arise during production. By automating the process, we minimize human handling and reduce the risk of contamination, ensuring that every face mask produced is safe and hygienic. Our commitment to quality is reflected in our partnerships with renowned brands such as Korea Mediheal, JAYJUN Cosmetic, and New Zealand Essano, among others. These collaborations underscore the reliability and effectiveness of our automatic bag filling machine in meeting industry standards.

Conclusion:

In conclusion, the Vippai VPD-400 Face Sheet Mask Machine is a game-changer for businesses in the skincare industry. With its advanced features and comprehensive production capabilities, our automatic bag filling machine not only enhances efficiency but also ensures consistent quality and safety. By choosing Vippai, you are investing in a solution that will transform your manufacturing processes, reduce labor costs, and address critical production challenges. Join us in revolutionizing your face mask production and experience the difference that Vippai can make for your business today!