In the ever-evolving world of skincare, innovation is key to staying ahead. At Vippai, we believe that every face mask tells a story of quality and care, and our VPD-400 Face Sheet Mask Machine is the heart of that narrative. Imagine a seamless production process where efficiency meets precision, allowing you to create luxurious face masks that pamper your customers’ skin. With state-of-the-art technology and user-friendly features, the VPD-400 transforms the art of mask-making into a streamlined, reliable operation. Join us as we explore how this innovative machine can redefine your skincare production and elevate your brand to new heights.

User-Friendly Operation with Stable Servo Settings

One of the standout features of the VPD-400 Face Sheet Mask Machine is its user-friendly design. Equipped with stable servo settings, this automatic filling and sealing machine ensures consistent performance, making it easy for operators to manage production with confidence. The intuitive interface allows users to seamlessly adjust settings, minimizing downtime and enhancing overall efficiency. By prioritizing ease of use, we help our clients maintain a smooth workflow, leading to higher productivity levels in face pack packaging.

Enhanced Safety with Balcony Layout Design

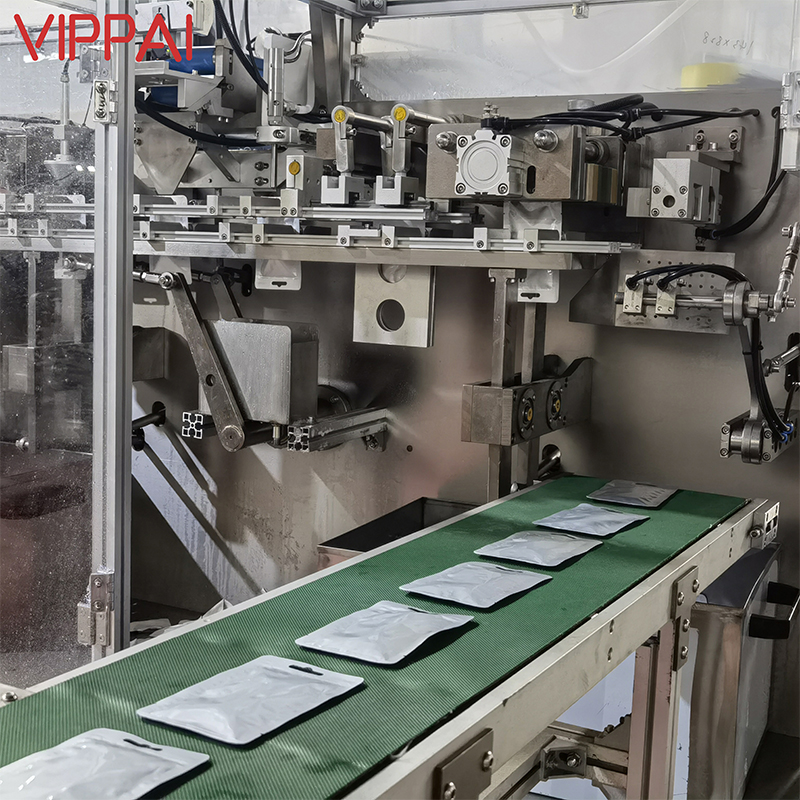

Safety is a top priority in any manufacturing environment. The VPD-400 features a balcony layout that separates the drive station from the workstation. This thoughtful design enhances safety and reliability, reducing the risk of accidents during operations. By keeping the mechanical components isolated from the working area, we create a safer environment for operators. Our commitment to safety not only protects your workforce but also ensures that production processes run smoothly, contributing to the overall effectiveness of face pack packaging.

Quality Control Through Manual Inspection

Quality assurance is essential in the cosmetics industry, and the VPD-400 excels in this area. The face sheet mask machine allows for manual inspection during the filling process, enabling operators to detect and remove any unqualified products, such as those with black spots, through online visual inspection. This capability ensures that only high-quality face masks make it to the final packaging, enhancing consumer satisfaction and brand reputation. By incorporating manual inspection into the production line, we help our clients maintain rigorous quality control standards in their face pack packaging processes.

Precise Filling with Advanced Metering Technology

Achieving accuracy in filling is crucial for effective face pack packaging, and the VPD-400 delivers on this front. Our face mask sheet making machine utilizes a high-end metering pump, achieving a filling accuracy of plus or minus 1 gram. This precision ensures that each face mask contains the correct amount of liquid essence, enhancing product consistency and quality. By investing in advanced metering technology, we enable our clients to produce face masks that meet the highest standards, reinforcing their brand’s commitment to excellence.

Conclusion:

In conclusion, the VPD-400 Face Sheet Mask Machine from Vippai offers a comprehensive solution for businesses looking to enhance their face pack packaging processes. With user-friendly operation, enhanced safety features, rigorous quality control, and precise filling capabilities, our machine is designed to meet the needs of modern skincare manufacturers. We are dedicated to helping our clients optimize their production lines and achieve operational excellence. Choose Vippai and experience the numerous benefits of our face mask production technology today!