At Vippai, we pride ourselves on providing versatile solutions that cater to the unique needs of our clients. Our automatic packaging line is designed to enhance the efficiency of your production process, especially for alcohol pad manufacturing. In this article, we will explore the flexibility offered by our machines and how they can be configured to optimize your operations.

Flexible Configuration Options

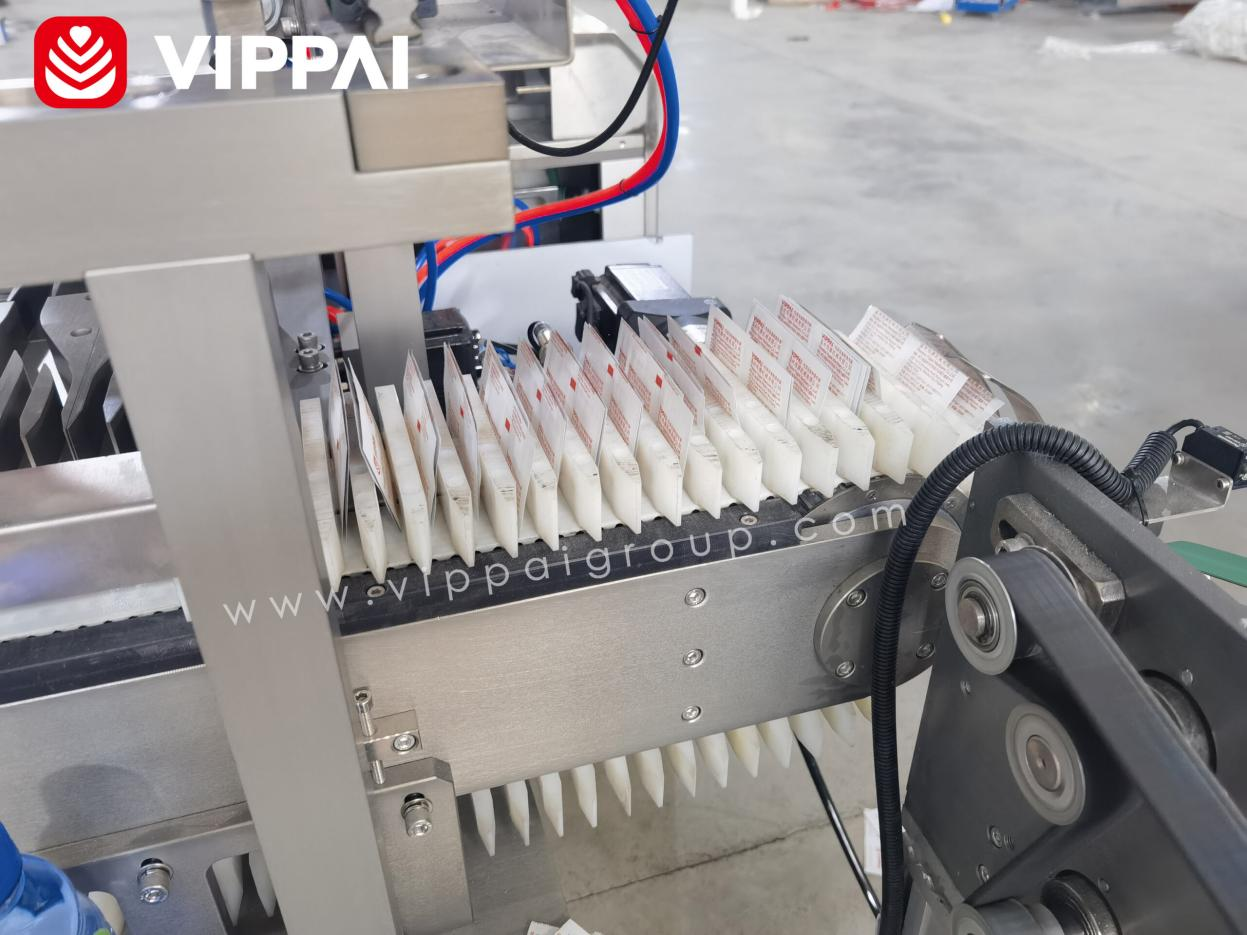

One of the standout features of our automatic packaging line is the flexibility it provides to our customers. We understand that every production facility has different requirements, which is why we offer various connection methods. Customers can choose to pair one alcohol pad machine with one automatic carton box packing machine, or they can opt for two alcohol pad machines working in tandem with a single automatic carton box packing machine. This adaptability allows you to scale your operations based on production demands and resource availability.

Increased Production Efficiency

By offering customizable configurations, we enable businesses to maximize their production efficiency. For instance, pairing two alcohol pad machines with one carton box packing machine can significantly increase output without requiring extensive additional labor. This setup not only enhances throughput but also optimizes floor space, allowing you to make the most of your production environment. We believe that an effective automatic packaging line should be tailored to fit your specific needs, and our flexible options do just that.

Streamlined Workflow

Integrating our alcohol pad machines with carton packing solutions creates a streamlined workflow that minimizes downtime. We ensure that each component of the automatic packaging line works seamlessly together, facilitating a smooth transition from production to packaging. This integrated approach reduces the likelihood of bottlenecks and enhances overall productivity. Our goal is to create a cohesive system that allows for continuous operation, enabling you to meet increasing market demands effectively.

Quality Assurance

At Vippai, we are committed to maintaining high standards of quality across our entire automatic packaging line. Each machine is designed to comply with rigorous industry standards, ensuring that your products are packaged securely and efficiently. Regular quality checks and maintenance are part of our process, giving you peace of mind that your production will consistently meet the highest benchmarks. This dedication to quality is what sets us apart in the industry and reinforces our commitment to our customers.

User-Friendly Operation

We prioritize the user experience in our machine design, recognizing that ease of operation is crucial for maximizing productivity. Our automatic packaging line features intuitive controls that allow operators to easily adjust settings and monitor the production process. This user-friendly approach reduces training time and empowers your staff to operate the machines confidently. We believe that a well-designed machine should enhance productivity while being accessible to all users.

Conclusion

In conclusion, Vippai's automatic packaging line is a versatile and efficient solution for alcohol pad manufacturing. With customizable configurations that allow for various connection methods, we empower our clients to optimize their production processes according to their specific needs.

By choosing our machines, you are not only enhancing your operational efficiency but also ensuring that your products are packaged to the highest quality standards. At Vippai, we are dedicated to supporting your success in the industry. Contact us today to learn more about how our automatic packaging line can benefit your business and help you achieve your production goals!