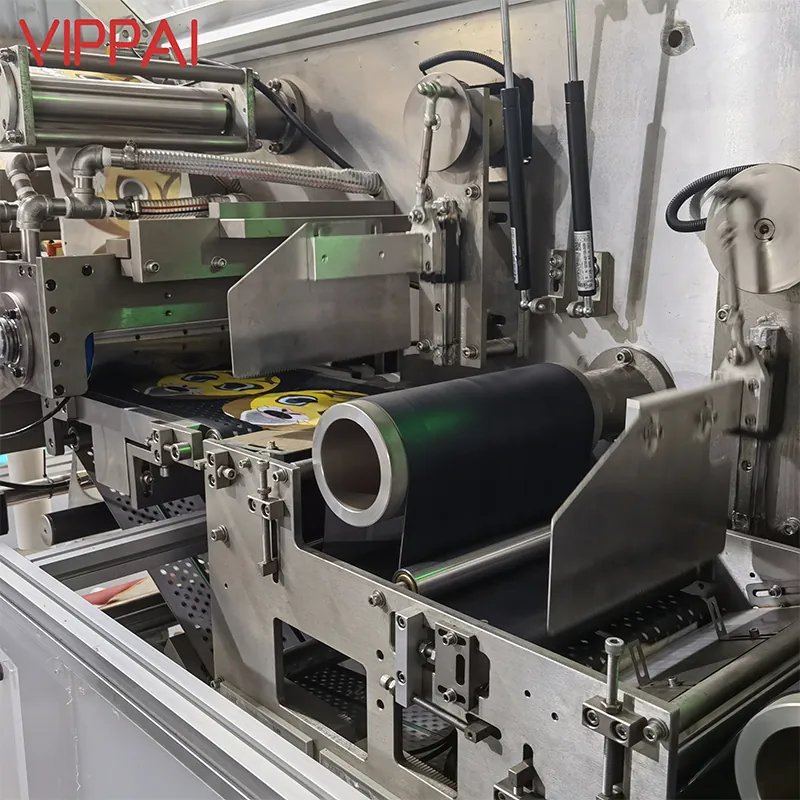

In the fast-paced cosmetics industry, efficiency and precision are vital to meet the increasing demand for high-quality face masks. We VIPPAI, a leading provider of cutting-edge packaging solutions, introduce the advanced Cosmetic Facial Mask Filling Machine. Designed to streamline the filling process for cosmetic face masks, this machine offers high-speed operation, accurate filling, and user-friendly controls. Let's explore the key features and benefits of the VIPPAI Cosmetic Facial Mask Filling Machine.

Efficient and High-speed Operation

The VIPPAI Cosmetic Face Mask Filling Machine ensures efficient and high-speed filling, enabling manufacturers to meet the growing demand for face masks. With its advanced technology, this machine can precisely fill face masks at a remarkable speed, enhancing productivity and reducing production time. By automating the filling process, the machine eliminates the need for manual labor, minimizing production costs and maximizing efficiency.

Accurate and Precise Filling

Accurate filling is crucial to maintain the quality and effectiveness of cosmetic face masks. Our Cosmetic Face Mask Filling Machine utilizes high-end metering pump technology, providing precise and consistent filling with an accuracy of plus or minus 1 gram. This level of precision ensures that each face mask receives the correct amount of essential liquids or ingredients, resulting in superior product quality and customer satisfaction. By eliminating variations in filling quantities, manufacturers can maintain their brand reputation and deliver reliable products to the market.

User-friendly Controls and Easy Adjustment

The VIPPAI Cosmetic Face Mask Filling Machine features a user-friendly interface and intuitive controls, making it easy to operate and adjust for different filling requirements. Manufacturers can easily set the desired filling parameters, such as filling volume and speed, through the machine's control panel. The machine also allows for quick and hassle-free adjustments to accommodate various face mask sizes and types, providing flexibility and versatility in production. With its user-friendly design, the VIPPAI Cosmetic Face Mask Filling Machine enables manufacturers to optimize their production processes with minimal training or technical expertise.

Enhanced Quality Control

Maintaining strict quality control is essential in the cosmetics industry. The VIPPAI Cosmetic Face Mask Filling Machine incorporates manual visual inspection capabilities, allowing operators to inspect the filling process for any irregularities manually. This feature enables quick identification and removal of any unqualified products or black spots, ensuring that only high-quality face masks reach the market. By integrating quality control within the filling process, manufacturers can uphold their quality standards and prevent defective products from reaching consumers.

Reliable After-sales Service

VIPPAI is committed to providing exceptional after-sales service to our partners. The VIPPAI Cosmetic Face Mask Filling Machine comes with a one-year warranty on all electrical parts, offering peace of mind to manufacturers. In the unlikely event of any technical issues, VIPPAI's team of skilled engineers provides prompt online assistance to resolve the problem. If required, VIPPAI can also arrange for on-site repairs by sending experienced technicians. This comprehensive after-sales support ensures uninterrupted production and maximum uptime for manufacturers.

Conclusion

Our Cosmetic Face Mask Filling Machine is a game-changer for cosmetic manufacturers seeking to boost efficiency, precision, and quality in their face mask production. With its high-speed operation, accurate filling, user-friendly controls, and enhanced quality control features, our machine empowers manufacturers to meet market demands effectively while maintaining superior product quality. VIPPAI's commitment to reliable after-sales service ensures manufacturers can rely on their investment for uninterrupted production. Choose the VIPPAI Cosmetic Face Mask Filling Machine and take your cosmetic manufacturing to new heights of efficiency and excellence.