Welcome to the future of face mask production! In a world where health and safety have taken center stage, Vippai's innovative face mask making machine is here to transform the way in mask production industry. With its cutting-edge heat seal technology, this state-of-the-art machine ensures not only top-notch quality but also unparalleled efficiency. Join us as we delve into the world of Vippai face mask making machine, exploring how it guarantees utmost comfort, durability, and protection for all.

What is Face Mask Making Machine?

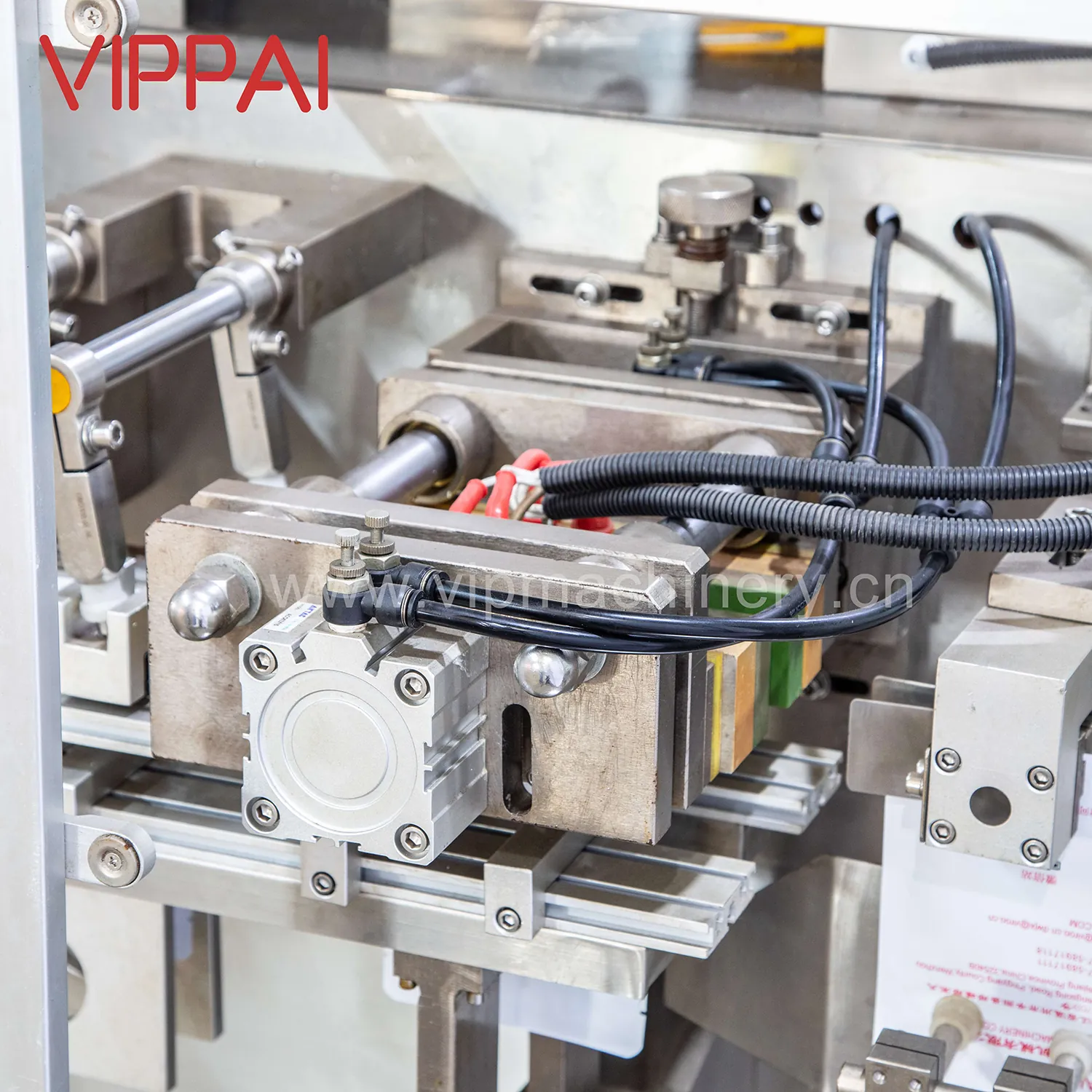

The main components of a face mask making machine include a material feeding system, ear loop welding unit, edge sealing mechanism, and a finished product output conveyor belt. The raw materials used in these machines are typically non-woven fabric or melt-blown fabric which are fed into the machine through the material feeding system.

Once inside the machine, various processes take place to turn these raw materials into finished face masks. One crucial step in this process is heat sealing technology - something that our face mask making machine specializes in.

How Does Vippai's Face Mask Making Machine Use Heat Seal Technology?

Vippai's face mask making machine utilizes heat seal technology as one of its key features to ensure the production of high-quality face masks. This technology involves the use of heat and pressure to create a strong bond between two materials, in this case, the layers of fabric used for making face masks.

The process begins by feeding multiple layers of non-woven fabric into the machine. These layers are then arranged in a specific manner to create a triple-layered mask with an inner layer for filtration, a middle layer for added protection, and an outer layer for durability. Once the fabrics are correctly aligned, they pass through heating elements that generate intense heat and pressure.

The combination of heat and pressure causes the fibers in the fabrics to melt and fuse together, creating a tightly sealed bond between them. This bond ensures that there are no gaps or holes in the fabric layers, which could compromise the effectiveness of the mask. The result is a strong and durable seal that can withstand repeated use without tearing or breaking.

One advantage of using heat seal technology is that it eliminates the need for any adhesives or chemicals to bind the fabric layers together. Adhesives can be harmful if they come into contact with skin or are inhaled while wearing a mask. With Vippai's face mask making machine, you can rest assured that your masks will be free from any potentially harmful substances.

Conclusion

Vippai's face mask making machine is a revolutionary solution to the current demand for high-quality and efficient face masks. By utilizing heat seal technology, it guarantees superior product quality and durability while also increasing production speed. This innovative machine has the potential to greatly impact the face mask industry and provide people with reliable protection against various health hazards. With commitment to excellence, our machines will continue to evolve and improve in order to meet our ever-changing needs in this fast-paced world. The future of face mask production looks promising with Vippai's cutting-edge technology at its forefront.