Rubbing alcohol pads are small pre-soaked wipes commonly used to disinfect skin and tiny areas. Highly portable and easy, these pads provide on-the-go antisepsis for cleaning wounds or readying the skin before procedures. However, their manufacturing process greatly impacts their shelf life and effectiveness over time. This article explores these two aspects. Read on for the answers!

Shelf Life of Rubbing Alcohol Pads: Key Influencing Factors

The typical shelf life of rubbing alcohol pads is 24-36 months when packaged and stored correctly. Still, a few variables can impact how long the antiseptic properties in alcohol pads endure. These include:

- Manufacturing Process: Strict quality control standards and sterile conditions in production ensure alcohol content and consistency batch-to-batch.This includes ensuring precise liquid injecting, UV sterilizing, four-side sealing, and defective rejecting.

- Quality of Ingredients: Using medical-grade alcohol and nonwoven materials helps maintain disinfecting ability over the shelf life. The use of medical-grade alcohol ensures that the pads have a high level of purity and are less likely to cause skin irritation or allergic reactions. Nonwoven materials, such as rayon or polyester, provide a suitable medium for the alcohol to be absorbed and released effectively.

- Packaging: Properly sealing pouches and sterilizing them with UV light prevents breakdown from light, air, and moisture exposure. The packaging should be airtight to prevent the evaporation of alcohol and the entry of contaminants. UV light sterilization of packaging materials before sealing ensures that no microorganisms can compromise the pads' sterility.

- Presence of Preservatives: Preservatives play a vital role in stabilizing the formulation of rubbing alcohol pads. Added preservatives like benzyl alcohol can protect the pad’s formulation when exposed to external factors.

- Storage Condition: Storing in a cool, dry place away from direct heat/sunlight replenishes the shelf life initially shortened during packaging. Exposure to heat or sunlight can cause the alcohol to evaporate more quickly, reducing the pads' effectiveness.

Manufacturing Process of Rubbing Alcohol Pads

The manufacturing process of rubbing alcohol pads is carefully designed and controlled to instil consistency and quality into each pad produced. It involves the following steps:

- Nonwoven fabric rolls are loaded into the machine and cut to appropriate size sheets.

- The fabric sheets are folded to form pouches, and alcohol is precisely pumped into the pouches using metered pumps.

- Package film moves through the line, and a colour code detection device tracks the film for quality control.

- The pouches are heat-sealed on all four sides using specialized heating machinery to fully enclose the alcohol within a pouch.

- Pouches undergo extensive quality checks such as sterility testing, ingredient verification, and colour code validation.

- Finished rubbing alcohol pads are packaged in medical-grade film pouches inside an ISO-certified clean room.

- The packaged pouches proceed to UV sterilization and may undergo additional labelling before release.

By choosing suppliers that meet strict material and production standards, manufacturers can build the best possible shelf life into their alcohol wipe pads. Using high-purity alcohols, implementing robust quality control processes, and sealing pouches with advanced barrier technologies all collaborate to shield pads from outside degradation factors. This allows alcohol pads to maintain their disinfecting strength for the duration of their labelled shelf life.

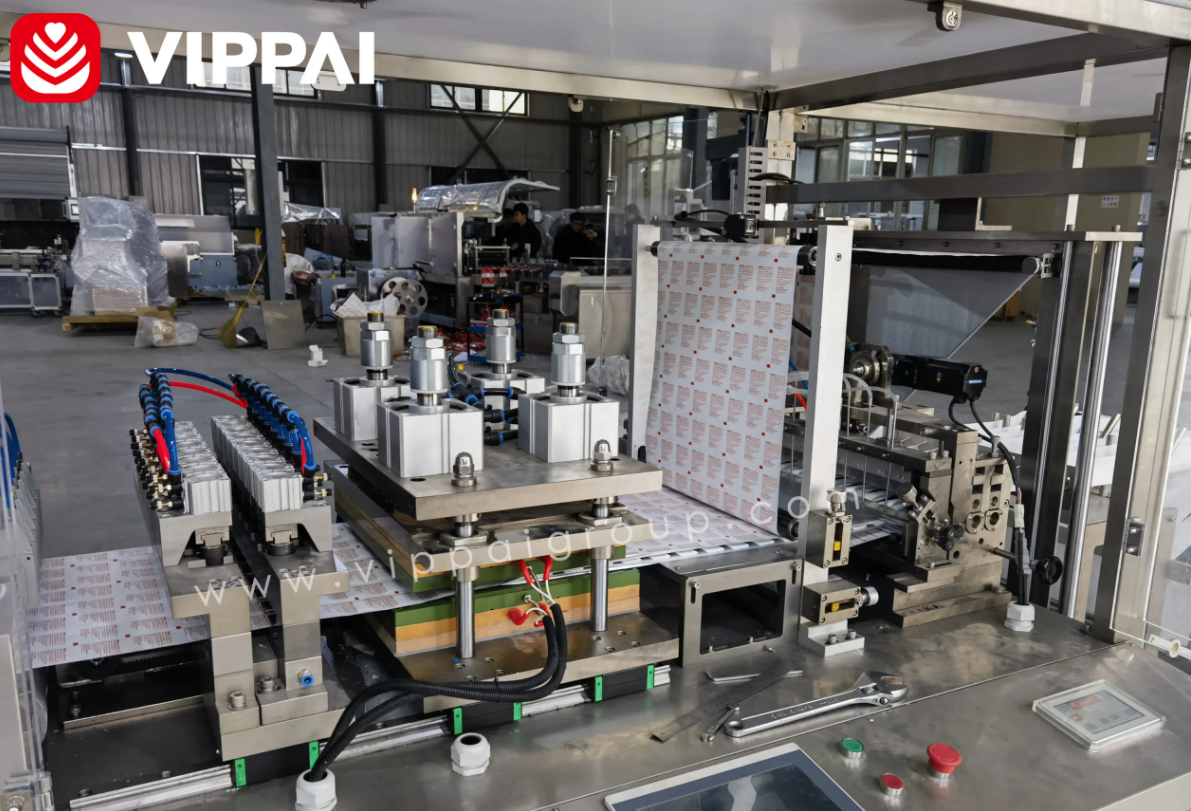

Product Highlight: VIPPAI VPD-800 Alcohol Pad Packaging Production Line

VIPPAI is a leading brand in automated packaging machinery. Over the years, it has attained technical expertise and national recognition as an innovator. The brand collaborates with major global manufacturers and offers a line of machines for alcohol pads, wet wipes, facial masks, and other products.

One of VIPPAI’s top offerings is the VPD-800 Alcohol Pad Packaging Production Line. It’s an integrated system for producing and packaging rubbing alcohol pads on an industrial scale. The VPD-800 combines an alcohol swab machine with fully automatic carton-packing equipment. In this way, it creates a streamlined process for alcohol prep pads bulk production. Some key attributes of this packaging line include:

- The ability to produce up to 8 pads simultaneously at speeds from 800-1200 pads per minute.

- Flexible connections allow various combinations of pad machines and carton box packing machines.

- Significant reductions in labour requirements and overall costs.

- High operational stability and adherence to industry safety standards.

- A glass safety cover ensures hygienic production.

Conclusion

Rubbing alcohol pads provide convenient portability and on-the-go disinfection capabilities. However, their shelf life depends strongly on how they are manufactured, packaged, stored, and handled throughout distribution. By implementing advanced production via equipment like the VIPPAI VPD-800, manufacturers can program maximum shelf lives into pads. They can also ensure consistent quality, assurance, and safety. The seasoned brand VIPPAI provides a range of automatic packaging machines. Visit our website to browse other reliable solutions for your packing and production needs.