Efficiency is key in the healthcare industry. Cotton swab production is important in the creation of a clean environment, plus the production of other essential items which aid in patient care and good hygiene. As consumer demand for high-quality cotton swabs continues to grow, manufacturers of healthcare-related goods must bring their production lines up to standards that will help them meet these expectations. One major step towards achieving this would be having installed cotton buds making machines for making cotton buds on their plant floor. Such equipment not only boosts productivity but also takes care of uniformity regarding product quality output — making them quite essential within present-day healthcare manufacturing environments.

Understanding Cotton Buds Making Machine

What a cotton buds-making machine does is take human intervention out of the process of cotton bud production. It handles the forming of the cotton buds to packaging ready for delivery with keen precision and promptness. Below are some key features of a typical cotton buds-making machine:

Unwinding Mechanism

The unwinding mechanism is the first step in the production process. It involves the careful unwinding of raw materials, such as the wooden or plastic sticks used for the cotton buds. This mechanism ensures that the raw materials are fed into the machine at a consistent speed, preventing any disruptions in the production flow.

Color Code Tracking System

The color code tracking system is essential for maintaining the quality and consistency of the cotton buds. This feature folds the packing film in half and uses the photo eyes to detect the colour mark to ensure precise packing. It helps in preventing mix-ups and ensures that the final product meets the required aesthetic and functional criteria.

Cut Rounded Corner Device

Safety and comfort are paramount in healthcare products, and the cut-rounded corner device plays a crucial role in this. It trims the cotton bud sticks’ edges to shape them and make them less rough. Therefore, safety is underscored for the cotton wool and additionally guarantees comfort for final consumers.

Bag Clamping Mechanism

The bag clamping mechanism is important for packaging because it keeps cotton buds safe inside the bags. It stops the bags from moving or getting damaged while the buds are packed.

Vibration Plate

The vibration plate plays a critical role in ensuring the smooth and efficient handling, sorting, and alignment of cotton buds, contributing to the overall effectiveness and productivity of the manufacturing process.

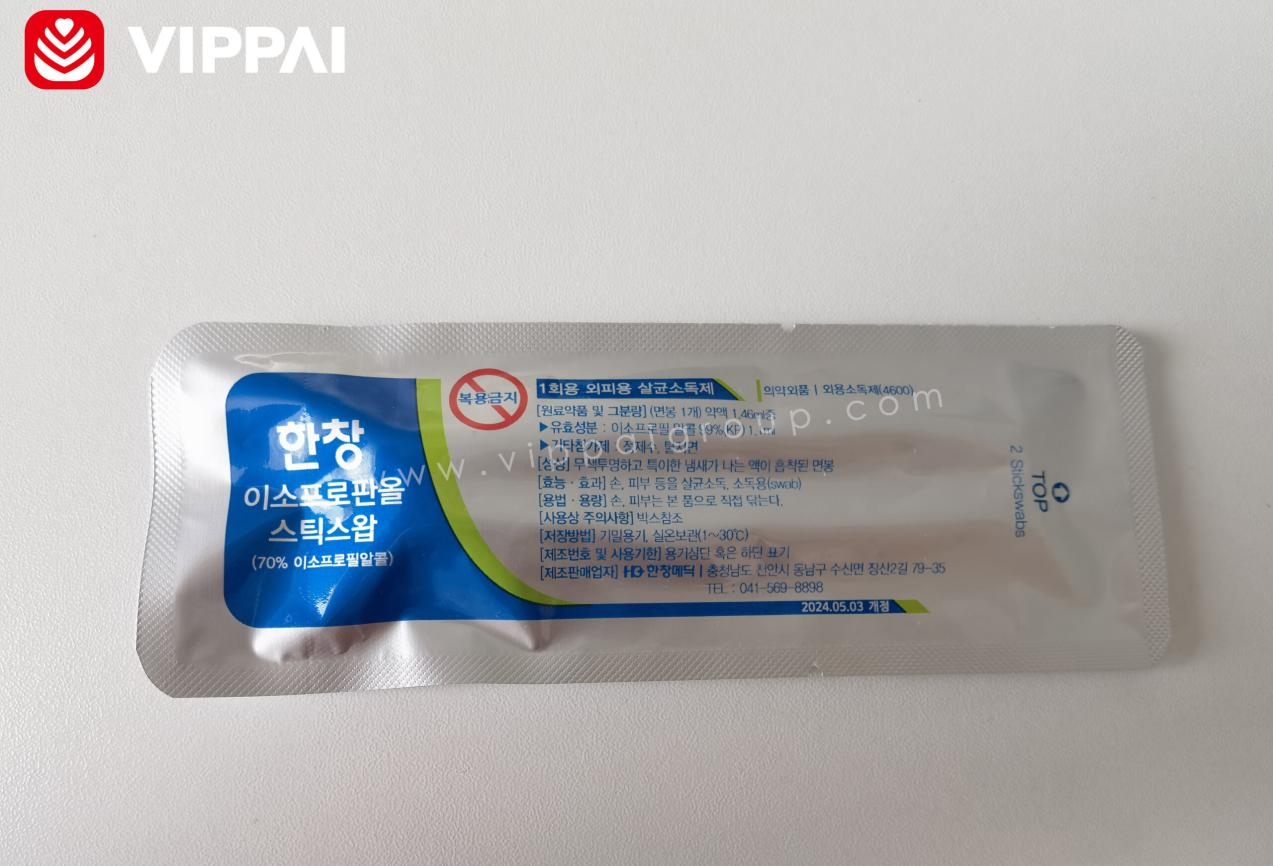

Liquid Adding

Sometimes, adding liquid-like disinfectants helps make cotton buds work better. This feature makes sure each bud gets just the right amount without wasting any.

Heat Sealing

The heat sealing method is used to close cotton bud packaging, making sure it’s airtight to keep the cotton buds clean and in good condition until they’re used. This is especially important in healthcare to maintain sterility.

How It Can Boost Your Healthcare Production Line

Adding a cotton buds-making machine to your healthcare production line can improve efficiency, quality, and cost-effectiveness.

Increased Efficiency

A cotton swab machine can greatly improve how fast and accurately you make them. It does all the work by itself, from starting making the cotton buds to finishing the packaging, which means you don’t need as many people working, and there’s less chance of mistakes. This leads to quicker production, helping you keep up with high orders without lowering the quality.

Consistency and Quality Control

Consistency is key in healthcare products, and a cotton buds-making machine ensures that every bud produced meets the same high standards. Features like the color code tracking system and cut rounded corner device work together to maintain the quality of each cotton bud, ensuring that your products are safe and effective for end-users.

Cost-Effectiveness

Buying a cotton buds-making machine costs a lot at first, but it saves money later on. The machine cuts down on worker costs by doing the work by itself and lessens waste by making sure materials are used just right. These savings can cover the cost of the machine over time, making it a good investment for your business.

Adjustable Mould

A key feature of a cotton buds-making machine is its adjustable mold. This feature lets you change the size and shape of the cotton buds to fit different needs. Whether you want regular-sized buds or unique designs, the adjustable mold lets you make many different products with the same machine.

VIPPAI’s VPD-250T Cotton Buds Swab-Making Packing Machine

For selecting the best cotton buds-making machine for your healthcare production, the VIPPAI VPD-250T Cotton Buds Swab Making Packing Machine is highly recommended. It’s a top option for fast, precise, and high-quality production. It comes equipped with all the essential features discussed earlier, including the unwinding mechanism, colour code tracking system, and heat sealing.

Moreover, the VIPPAI VPD-250T has cutting-edge technology that reduces interruptions and maintenance, keeping your production line operating efficiently. It can handle different types of cotton swabs, from wooden cotton buds to stick cotton, making it suitable for various production requirements.

Most importantly, the VIPPAI VPD-250T has simple controls, making it easy for beginners to use. It fits well with your current production line, improving efficiency and output.

Conclusion

Adding a machine that makes cotton buds to your healthcare production line is a smart choice for improving speed, reliability, and cost-effectiveness. The VIPPAI VPD-250T is a good option because it’s sturdy and can make different types of cotton buds. Buying this machine helps your line keep up with the increasing needs of the healthcare field and keep high-quality products. So, why wait? Order now!